Couture Dog Clothes Manufacturers | Luxury Pet Apparel Wholesale

Advanced Manufacturing for Premium Pet Apparel

In the burgeoning pet industry, the demand for high-quality, specialized apparel has never been higher. For discerning brands and retailers, partnering with premier couture dog clothes manufacturers is paramount to success. This specialized segment demands not only aesthetic appeal but also exceptional durability, comfort, and compliance with stringent pet safety standards. Our focus in this technical overview is on the intricate processes, strategic advantages, and critical considerations offered by leading manufacturers in this specialized domain.

The market for pet apparel, particularly luxury and custom lines, has expanded significantly, driven by a global trend of pet humanization. Pet owners increasingly view their companions as integral family members, deserving of the same quality and care in clothing as human garments. Manufacturers are responding by integrating advanced textile technologies, precision engineering, and innovative design methodologies to produce garments that stand out in terms of design sophistication, functional performance, and long-term durability. This shift necessitates a deeper understanding of the manufacturing ecosystem and the technical capabilities required to deliver excellence in pet couture.

Industry Trends in Couture Dog Apparel Manufacturing

The landscape of pet fashion and functional apparel is continually evolving, influenced by several pivotal trends that dictate manufacturing practices and product development. Staying abreast of these trends is crucial for brands and their manufacturing partners.

- • Sustainability & Ethical Sourcing: A growing consumer consciousness demands eco-friendly materials such as organic cotton, recycled polyester, hemp, and biodegradable fibers. Leading manufacturers are adopting sustainable dyeing processes, minimizing water and energy consumption, and implementing robust waste reduction and recycling programs within their facilities to meet certifications like GOTS and Bluesign.

- • Technological Integration & Automation: The adoption of advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems is now standard. These technologies facilitate precise pattern grading across a vast array of dog sizes and breeds, optimize fabric utilization to reduce waste, and enhance cutting and stitching consistency through automation. This level of precision is fundamental for competitive couture dog clothes manufacturers.

- • Advanced Material Science: The integration of high-performance textiles is expanding beyond human athletic wear into pet apparel. This includes fabrics with properties like enhanced breathability (e.g., MVTR ratings), advanced waterproofing (e.g., 2-layer and 3-layer laminated fabrics with hydrostatic head ratings), anti-microbial treatments, UV protection, and even smart textiles with integrated sensors for health monitoring.

- • Customization & Personalization at Scale: While couture implies bespoke, the trend extends to offering customizable elements on a broader scale. This ranges from specific colorways and material combinations to personalized embroidery or sublimation printing. Manufacturers are developing flexible production lines to handle small-batch, high-variation orders efficiently, catering to distinct brand identities and niche markets, including specialized lines from fall clothes for dogs manufacturers.

- • Health and Wellness Integration: Beyond simple protection, pet apparel is being designed with therapeutic benefits. Examples include anxiety-reducing compression garments, post-operative recovery suits with strategic openings for accessibility, and mobility support harnesses. This necessitates a deep understanding of canine anatomy and veterinary requirements.

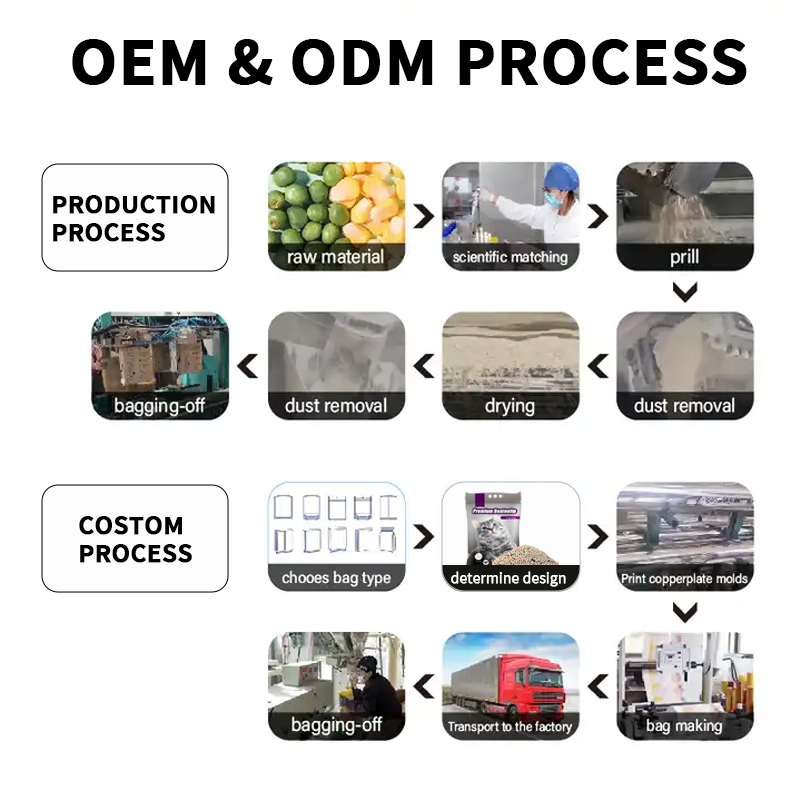

Detailed Manufacturing Process Flow for Couture Dog Apparel

The production of high-end dog apparel is a meticulously engineered, multi-stage process that prioritizes precision, material integrity, and specialized craftsmanship. This ensures both aesthetic excellence and functional superiority.

1. Conceptualization and Design Engineering

- • Design Brief & Market Analysis: Collaboration with brands to define design concepts, target demographics (e.g., breed types, activity levels), and specific functional requirements (e.g., warmth, waterproofing, aesthetic). Market research informs trend integration and competitive positioning.

- • Material Research & Selection: Fabrics are chosen based on a comprehensive analysis of their aesthetic appeal, tactile properties, durability (e.g., abrasion resistance, tear strength), breathability, and pet safety (hypoallergenic, non-toxic). This includes performance textiles, natural fibers, and luxury synthetics. Suppliers must meet certifications such as Oeko-Tex Standard 100 or GOTS.

- • Pattern Development (CAD/CAM): Digital patterns are meticulously drafted using advanced Computer-Aided Design (CAD) software. This enables precise measurement, intricate pattern piece manipulation, and efficient grading across an extensive range of sizes (e.g., from toy breeds to extra-large working dogs). Parametric design ensures optimal fit and minimizes material waste. Initial prototypes are digitally simulated to check drape and fit.

- • Prototyping & Fit Testing: A physical sample is created from the initial pattern. This prototype undergoes rigorous fit testing on a diverse range of live models or specialized mannequins to assess comfort, freedom of movement, and overall aesthetic. Iterative adjustments are made to the pattern and construction until optimal performance and appearance are achieved.

2. Material Procurement and Preparation

- • Incoming Material Inspection: All raw materials, including fabrics, threads, zippers, buckles, and embellishments, undergo stringent quality control upon arrival. This involves verifying specifications against purchase orders, inspecting for defects (e.g., color inconsistencies, weave flaws), and confirming adherence to industry standards (e.g., color fastness, shrinkage rates).

- • Fabric Spreading: Fabrics are carefully laid out in multiple, precise layers on automated cutting tables. Advanced spreading machines ensure consistent tension, alignment, and absence of wrinkles, which are critical for accurate cutting.

3. Precision Cutting

- • Automated CNC Cutting: Computerized Numerical Control (CNC) cutting machines, often employing oscillating blades or laser technology, are used to precisely cut multiple layers of fabric according to the optimized digital patterns generated by the CAD system. Vacuum-holddown systems ensure fabric stability during cutting. This minimizes material waste and guarantees unparalleled cutting accuracy, a hallmark of leading couture dog clothes manufacturers.

- • Piece Bundling & Labeling: Cut fabric pieces are meticulously sorted, numbered, and bundled for each garment. Digital tracking systems ensure accurate allocation to specific production lines and sizes.

4. Assembly, Embellishment, and Finishing

- • Specialized Sewing: Highly skilled technicians operate industrial sewing machines tailored for different fabric types and stitch requirements. Techniques include flatlock stitching for comfort and durability, overlock for neat seam finishing, and specialized topstitching for aesthetic appeal. Seam integrity, stitch density (e.g., minimum 8-12 stitches per inch), and thread tension are continuously monitored. For waterproof garments, seam taping is applied using specialized heat-sealing machinery.

- • Embellishment & Detailing: This critical stage involves the precise application of decorative elements such as embroidery, appliqué, heat transfers, screen printing, and the attachment of hardware (zippers, snaps, buckles, D-rings). For couture pieces, this may include hand-beading, crystal application, or custom laser etching.

- • Labeling & Branding: Care labels, sizing labels, and brand tags are securely attached. These often adhere to international labeling standards (e.g., ISO 3758 for care symbols).

5. Rigorous Quality Control and Packaging

- • In-Line Quality Assurance: Continuous quality checks are performed at each stage of the assembly process to identify and rectify any deviations from specifications early, minimizing rework and ensuring consistency.

- • Final Product Inspection (FPI): Every finished garment undergoes a comprehensive final inspection. This includes visual checks for aesthetic flaws, measurement verification against size charts, functional testing of closures and hardware, and detailed scrutiny of stitching integrity. Compliance with specified performance parameters (e.g., waterproof ratings, breathability) is also re-verified.

- • Pressing, Folding & Packaging: Garments are professionally pressed, meticulously folded, and packaged according to client specifications, often including custom polybags, hang tags, and branded tissue paper, ready for shipment.

Testing Standards and Target Industries

Leading manufacturers of couture dog apparel adhere to rigorous international testing standards to guarantee product safety, durability, and quality. These include:

- • ISO 9001: Certification for Quality Management Systems, ensuring consistent process control and product quality.

- • Oeko-Tex Standard 100: Certifies textiles free from harmful substances, which is critical for direct skin contact and pet safety.

- • ASTM & AATCC Standards: For specific material testing such as tear strength (ASTM D1424), abrasion resistance (ASTM D3884), colorfastness (AATCC 8, 15, 61), and flammability (ASTM D1230), crucial for assessing textile performance and safety.

Target industries for these advanced manufacturing services include high-end pet fashion brands, luxury pet boutiques, specialized online retailers focusing on premium and technical pet products, and niche markets requiring custom animal attire such as show dog outfits, professional service dog vests, and veterinary protective wear.

Technical Specifications and Performance Parameters

The technical specifications for high-performance pet apparel are paramount for ensuring product integrity, pet welfare, and meeting the discerning demands of the luxury market. Brands rely on manufacturers to meet stringent benchmarks for materials, construction, and overall performance.

These detailed specifications ensure that garments from leading couture dog clothes manufacturers are not only aesthetically captivating but also highly functional, exceptionally durable, and ultimately safe and comfortable for pets. Rigorous adherence to these technical parameters is a primary differentiator in the premium pet apparel market.

Application Scenarios and Technical Advantages

The diverse application of high-quality dog apparel requires tailored solutions, each benefiting from specific technical advantages provided by expert manufacturers. These advantages transcend basic garment construction to offer enhanced utility and pet well-being.

- • Extreme Weather Protection: For canine companions in harsh environments, insulated, waterproof, and windproof coats are indispensable. Technical advantages include multi-layer construction with advanced thermal insulation (e.g., synthetic down or Thinsulate™), fully seam-sealed fabrics with high hydrostatic head ratings (e.g., 15,000mm+), and breathable membranes (e.g., 10,000 MVTR) to prevent condensation. Ergonomic patterning ensures full range of motion, which is crucial for active dogs and a key offering from fall clothes for dogs manufacturers.

- • Post-Surgical and Medical Recovery: Specialized recovery suits offer critical protection for surgical sites, wounds, or skin conditions, preventing licking, scratching, and external contamination. Advantages include ultra-soft, hypoallergenic, and highly breathable fabrics (e.g., bamboo blends, modal), four-way stretch for adaptive fit, and strategically placed, secure closures that allow easy veterinary access and hygienic toileting without garment removal.

- • High-End Fashion & Brand Differentiation: Luxury pet fashion lines demand exquisite tailoring, premium materials, and intricate detailing. Manufacturers provide technical advantages in sophisticated embellishment techniques (e.g., specialized embroidery, appliqué, crystal application), precision pattern matching for complex designs, and expertise in working with delicate or high-value fabrics like silk, cashmere, or ethical faux fur, ensuring brand identity is perfectly translated into a wearable art piece.

- • Working & Service Dog Apparel: Garments for service animals, police K9s, or search and rescue dogs require extreme durability, specific functional features, and high visibility. Technical advantages include reinforced stitching at stress points (e.g., bartacks, box-stitching), robust, quick-release hardware, modular designs for attachment of specialized equipment (e.g., MOLLE systems), and integrated highly reflective materials meeting ANSI/ISEA 107 standards for occupational safety.

- • Sporting and Performance Gear: For agility, hunting, or tracking dogs, apparel must enhance performance without hindrance. Technical benefits include lightweight, moisture-wicking fabrics for temperature regulation, aerodynamic fits to reduce drag, and protective layers against abrasions or thorns, all while maintaining maximum flexibility and comfort.

These varied scenarios clearly illustrate the diverse technical requirements and the critical importance of partnering with manufacturers capable of delivering highly specialized, performance-driven solutions that extend far beyond mere aesthetic appeal.

Vendor Comparison: Key Differentiators for Couture Dog Apparel Manufacturers

The selection of an appropriate manufacturing partner is a strategic decision for brands aiming to succeed in the high-end dog apparel market. A detailed comparative analysis is essential, focusing on differentiators that extend well beyond initial pricing to encompass long-term value, quality, and partnership capabilities.

For brands targeting the premium and luxury pet apparel segments, investing in a Tier 1 manufacturer offers unparalleled quality, sophisticated design flexibility, and a profound commitment to ethical, sustainable, and technically superior production. This strategic partnership ensures brand integrity and competitive advantage in a discerning market.

Customized Solutions for Unique Pet Apparel Lines

The defining characteristic of a truly exceptional couture dog clothes manufacturers is its profound capability to provide bespoke manufacturing solutions. This extends far beyond simple private labeling, encompassing a deep, collaborative partnership in product development that brings a brand's unique vision to life.

- • Integrated Design & Development Partnership: Leading manufacturers often house expert in-house design and technical teams. These specialists work intrinsically with clients, transforming initial concepts, sketches, or even abstract ideas into meticulously engineered, production-ready patterns and prototypes. This includes specialized anthropometric pattern making to cater to the anatomical nuances of various dog breeds, ensuring an optimal, comfortable, and functional fit.

- • Advanced and Niche Material Sourcing: Access to an extensive global network of certified textile and hardware suppliers is a key strength. This allows for sourcing highly specialized materials—from performance fabrics with specific technical properties (e.g., advanced moisture-wicking, anti-microbial, specialized UV protection) to rare, ethically sourced luxury fibers like high-grade cashmere or specialized waterproof leathers. Manufacturers can also facilitate the development of custom-blended fabrics or unique finishes to meet precise brand requirements.

- • Flexible and Agile Production Runs: Modern manufacturing facilities are engineered for flexibility. They utilize modular production lines and agile scheduling to effectively handle diverse order sizes and varying complexities. This supports everything from limited-edition couture collections (low MOQs) to scalable production for popular items, allowing brands to test market demand and scale without prohibitive initial investments.

- • Integrated Branding and Packaging Solutions: Beyond garment production, comprehensive manufacturers offer bespoke branding integration. This includes custom-designed labels, hang tags, specialized hardware (e.g., custom-engraved buckles), unique embellishment techniques, and sophisticated packaging solutions (e.g., custom boxes, dust bags) that consistently reinforce the brand's luxury identity and premium market positioning.

- • Technical Innovation and R&D Support: Forward-thinking manufacturers actively engage in research and development. They can assist clients in exploring new textile technologies, developing innovative functional features (e.g., integrated GPS pockets, reflective safety elements), or adapting human fashion trends for canine application, providing a significant competitive edge.

Application Case Studies & Customer Feedback

Real-world applications powerfully demonstrate the tangible impact of superior manufacturing capabilities in the competitive pet apparel sector. These case studies highlight the successful outcomes of strategic partnerships.

Case Study 1: Launch of a Luxury Performance Winter Collection

A prominent luxury pet brand, "Alpine Paws," approached a specialized couture dog apparel manufacturer to develop an exclusive line of ultra-warm, highly durable, and aesthetically sophisticated winter jackets for large Northern breeds such as Huskies, Malamutes, and Samoyeds. The core challenge was to integrate cutting-edge thermal performance with a refined, high-fashion aesthetic suitable for urban environments and wilderness adventures alike. The manufacturer engineered a custom three-layer fabric system: an outer shell featuring a 20,000mm waterproof/breathable membrane with a DWR finish, a middle layer of sustainably sourced, high-loft synthetic insulation (equivalent to 700-fill down), and a soft, anti-static inner lining for maximum comfort. All seams were fully taped using a proprietary heat-sealing process to ensure absolute waterproofing. The ergonomic pattern design, developed using 3D CAD modeling, ensured complete freedom of movement and a perfect fit across diverse canine anatomies. The resulting "Summit Series" collection garnered critical acclaim in luxury pet publications and achieved unprecedented sales, significantly bolstering Alpine Paws' market position as a leader in premium, performance-driven pet wear. Customer feedback consistently highlighted the jackets' exceptional warmth (tested down to -30°C), superior durability in extreme conditions, and elegant, non-restrictive fit.

Case Study 2: Development of an Eco-Conscious Canine Recovery Wear Line

"HealPaws," an innovative pet wellness brand, sought a manufacturing partner capable of producing a line of eco-friendly, medically approved recovery suits for post-surgical care and anxiety relief. The brand's mission focused on holistic pet well-being and environmental responsibility. The chosen manufacturer, renowned for its sustainable practices and technical textile expertise, collaborated closely with HealPaws' veterinary consultants. The solution involved sourcing GOTS-certified organic cotton blended with bamboo fibers for superior softness, breathability, and natural anti-bacterial properties. The garment design incorporated strategic, non-restrictive stretch panels and an innovative, pet-safe magnetic closure system for easy veterinary inspection and hygienic access. The entire production process was optimized for minimal water usage and zero-waste fabric cutting, with all offcuts recycled into new materials. This partnership resulted in the "Serenity Suit" collection, which quickly became a bestseller, praised by veterinarians and pet owners alike for its comfort, effectiveness in promoting healing, and verifiable eco-credentials. HealPaws reported a 45% increase in brand trust and customer retention, directly attributing this success to the ethical and technically advanced manufacturing capabilities of their couture dog clothes manufacturers partner.

Ensuring Trustworthiness: FAQ, Lead Times, Warranty & Support

Establishing strong B2B partnerships relies on transparency, clear communication, and robust support systems. Here, we address common client concerns regarding manufacturing collaboration.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom order of couture dog apparel, from concept to delivery?

- A: For fully customized designs requiring new pattern development and specialized material sourcing, the process typically ranges from 12-16 weeks. This comprehensive timeline accounts for design engineering, multiple prototyping iterations, material procurement, precision manufacturing, multi-stage quality control, and final logistics. For repeat orders or designs utilizing existing patterns, lead times are generally shorter, typically 8-10 weeks.

- Q: What are the Minimum Order Quantities (MOQs) for bespoke dog clothes manufacturing?

- A: MOQs for bespoke couture dog apparel projects typically start from 100-200 units per style, per colorway. This minimum can vary based on the complexity of the design, the exclusivity of materials involved, and specific embellishment requirements. We strive to maintain flexibility to support both emerging brands and limited-edition collections, offering competitive MOQs without compromising quality.

- Q: How do you ensure the safety and long-term comfort of pets wearing your manufactured garments?

- A: Pet safety and comfort are paramount in our manufacturing philosophy. We exclusively utilize Oeko-Tex Standard 100 certified fabrics, guaranteeing they are rigorously tested and free from harmful chemicals. Our designs prioritize ergonomic fit, non-restrictive movement, and incorporate pet-safe, durable hardware. All garments undergo extensive testing for material durability (e.g., tensile strength, abrasion resistance), colorfastness, shrinkage, and functional integrity to meet or exceed industry safety and performance benchmarks before final dispatch.

- Q: Can your manufacturing process accommodate highly specific size ranges or specialized anatomical needs for diverse dog breeds?

- A: Absolutely. Our advanced CAD pattern development systems are specifically designed for precise pattern grading across an exceptionally wide spectrum of sizes, accommodating everything from the smallest toy breeds to the largest giant breeds. We excel in developing custom size charts based on client-provided anthropometric measurements, breed-specific data, or by working closely with veterinary professionals to ensure an optimal, comfortable, and functional fit for every canine physique.

Lead Time and Fulfillment Details

Our standard production lead time, meticulously calculated from final sample approval to shipment, ranges between 8-12 weeks. This timeframe accounts for comprehensive material procurement, precision manufacturing processes, multi-stage quality control, and careful, custom packaging. For urgent projects, expedited options may be available depending on current production capacity and material stock, subject to agreed-upon additional fees. We partner with a network of reliable and established logistics providers to ensure efficient, secure, and timely global delivery of all orders, managing all necessary documentation and customs procedures.

Warranty Commitments

We maintain an unwavering commitment to the quality and craftsmanship of our manufactured products. All garments produced by us are backed by a limited warranty against manufacturing defects for a period of 6 months from the date of ex-factory shipment. This warranty specifically covers issues arising from faulty materials or substandard workmanship under normal wear and care conditions. Claims are processed with utmost efficiency and transparency upon thorough verification of the defect, with solutions ranging from prompt repair, full replacement of the defective units, or issuance of a credit note, ensuring client satisfaction and product integrity.

Comprehensive Customer Support Information

Our client-centric approach is anchored by dedicated account managers who serve as a singular point of contact for all client communications. This streamlined support extends from the initial inquiry and design phase through the entire production lifecycle, including post-delivery after-sales support. We offer comprehensive support channels via direct email, scheduled phone consultations, and secure video conferences during standard business hours. For any technical inquiries, production updates, or urgent assistance, our experienced team is committed to providing prompt, informed, and effective solutions, ensuring a seamless, communicative, and highly satisfactory partnership experience.

Conclusion

The dynamic landscape for couture dog clothes manufacturers is increasingly defined by technological innovation, manufacturing precision, and an unwavering commitment to both quality and ethical practices. For brands aspiring to excel in this highly competitive and specialized market, the strategic selection of a manufacturing partner possessing advanced technical capabilities, a robust quality assurance framework, and a proven dedication to customized, solution-oriented production is not merely advantageous, but absolutely non-negotiable. This holistic focus on sophisticated design, superior material science, durable construction, and pet-centric ergonomics ensures the development of products that consistently exceed both regulatory standards and evolving consumer expectations, solidifying a brand's reputation for excellence.

References

- Textile Industry Affairs. "Advancements in Sustainable Textile Manufacturing for Pet Products and Specialty Apparel." Journal of Textile Engineering and Design, Vol. 45, No. 2, pp. 112-128, 2023.

- International Organization for Standardization. "ISO 9001:2015 Quality management systems – Requirements." Geneva, Switzerland, 2015.

- Oeko-Tex Association. "Oeko-Tex Standard 100: Testing for harmful substances in textiles." Zurich, Switzerland, 2024.

- Pet Industry Global Market Analysis. "The Rise of Luxury Pet Apparel: Market Drivers, Consumer Behavior, and Technical Demands." Global Pet Market Insights Report, 2023-2024.

- American Society for Testing and Materials (ASTM). "ASTM D5034 / D5034M-21: Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)." West Conshohocken, PA, 2021.