- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Couture Dog Clothes Factory: Luxury Custom & Fall Pet Apparel

The Advanced Capabilities of a couture dog clothes factory: Driving Innovation in Pet Apparel

In the rapidly expanding pet care industry, the demand for high-quality, aesthetically superior, and functional pet products is at an all-time high. This trend extends beyond basic necessities to luxury items, with a significant surge in the market for bespoke pet apparel. A leading couture dog clothes factory plays a pivotal role in this niche, providing specialized manufacturing services that cater to the exacting standards of luxury pet brands, boutique designers, and high-end retailers. These facilities are not just production lines; they are centers of innovation, blending traditional craftsmanship with advanced manufacturing technologies to create garments that prioritize pet comfort, durability, and style.

The scope of a modern pet product manufacturer often extends beyond a single category, encompassing a diverse range of items. For instance, a manufacturer adept at producing `fall clothes for dogs factory` output might also leverage its quality control and supply chain expertise to excel as a `fresh & natural cat litter manufacturer` or a `fresh & natural cat litter supplier`. This cross-category proficiency highlights a robust manufacturing infrastructure and a deep understanding of the broader pet consumer market, ensuring consistent quality and adherence to specific product requirements, whether it's for premium apparel or advanced pet hygiene solutions.

Detailed Manufacturing Process Flow at a Couture Dog Clothes Factory

The production of couture dog clothes is an intricate process demanding precision, specialized machinery, and skilled artisans. A top-tier couture dog clothes factory adheres to a rigorous multi-stage workflow to ensure every garment meets the highest standards of quality and design.

-

Phase 1: Design & Pattern Engineering (CAD/CAM Integration)

This initial phase involves conceptualizing designs based on client specifications, market trends, or internal creative direction. Utilizing advanced Computer-Aided Design (CAD) software, designers create detailed sketches and 3D renderings. Pattern engineers then translate these designs into precise patterns, taking into account various dog breeds, sizes, and anatomical considerations. Computer-Aided Manufacturing (CAM) systems optimize pattern layouts for fabric efficiency, minimizing waste. Materials selection is critical here, focusing on pet-safe, durable, and comfortable textiles such as organic cottons, bamboo blends, technical performance fabrics, or responsibly sourced fine wools and silks. Testing includes fabric drape analysis and stress point identification for garment longevity.

-

Phase 2: Material Sourcing & Preparation

Only premium materials are sourced, often certified to standards like OEKO-TEX Standard 100 for harmful substances, ensuring pet safety. Fabrics undergo pre-shrinking and colorfastness tests (e.g., AATCC test methods) to prevent future distortion and fading. Trims, embellishments (e.g., Swarovski crystals, custom embroidery threads, specialized fastenings), and hardware are also meticulously selected for quality and durability. This stage is crucial for ensuring the integrity of the final product and meeting specific client requirements, especially for luxury collections.

-

Phase 3: Precision Cutting & Embellishment

Fabrics are cut using automated CNC cutting machines for unparalleled precision, ensuring consistent sizing across batches. For delicate or intricate patterns, skilled manual cutting may still be employed. Embellishments such as intricate embroidery, appliqué work, heat transfers, or custom digital printing are applied at this stage, often using multi-head embroidery machines or specialized printing equipment. These processes are meticulously controlled to maintain design integrity and durability.

-

Phase 4: Assembly & Stitching (Specialized Techniques)

Garment components are assembled by experienced sewers using industrial-grade machines capable of various stitch types (e.g., lockstitch, overlock, coverstitch) suitable for different fabric weights and garment areas. Flatlock seams are frequently used for comfort, preventing chafing. Reinforced stitching is applied at stress points such as leash attachment areas, armholes, and necklines to enhance service life. This stage often involves specialized techniques for complex designs or unique material pairings.

-

Phase 5: Finishing & Quality Control (QC)

Finished garments undergo a comprehensive multi-point quality control inspection. This includes checking seam integrity, embellishment security, size accuracy against specifications, color consistency, and overall aesthetic appeal. Any loose threads are trimmed, and garments are pressed or steamed to ensure a pristine finish. Testing standards often include tensile strength testing for fabric and seams, snap/zipper durability tests, and colorfastness after washing (per ISO/ASTM standards). This rigorous QC process ensures that each piece leaving the couture dog clothes factory meets global quality benchmarks.

-

Phase 6: Packaging & Dispatch

Each garment is carefully folded, individually bagged (often in biodegradable packaging for eco-conscious brands), and then packaged according to client specifications, which may include custom hang tags, labels, and boxes. Logistics are coordinated for efficient and secure global dispatch to target industries such as luxury pet boutiques, online high-end pet retailers, and custom pet wear brands.

Image: State-of-the-art production line in a modern couture dog clothes factory.

Advantages in typical application scenarios include enhanced energy saving through optimized material utilization and efficient machinery, as well as superior durability and aesthetic appeal through rigorous material selection and testing standards, crucial for premium pet products.

Industry Trends & Market Dynamics in Pet Apparel and Care

The pet industry is characterized by dynamic growth and evolving consumer preferences. Key trends influencing a couture dog clothes factory include:

- Sustainability & Ethical Sourcing: There's increasing demand for eco-friendly materials (organic cotton, recycled fabrics) and transparent supply chains. A reputable couture dog clothes factory will prioritize these practices.

- Personalization & Customization: Bespoke designs, monogramming, and made-to-measure services are highly sought after by luxury pet owners.

- Technological Integration: While not yet mainstream for apparel, smart wearables for pet health monitoring are emerging, suggesting future integration opportunities.

- Seasonal Collections: The market for `fall clothes for dogs factory` and other seasonal wear continues to expand, driven by human fashion trends applied to pets.

- Holistic Pet Wellness: This trend extends beyond food and vet care to premium accessories, including apparel, and high-quality hygiene products like those offered by a `fresh & natural cat litter manufacturer` or `fresh & natural cat litter supplier`. Consumers are increasingly willing to invest in products that contribute to their pets' overall well-being.

These trends emphasize quality, innovation, and ethical production, pushing manufacturers to continuously upgrade their processes and material offerings.

Technical Specifications & Product Parameters (Pet Apparel & Litter)

Technical specifications are paramount for B2B decision-makers. For a couture dog clothes factory, parameters include fabric composition, weave density (e.g., thread count), tensile strength (ASTM D5034), colorfastness to washing and light (AATCC Test Method 61), abrasion resistance (Martindale test), and specific sizing tolerance (e.g., +/- 0.5 cm). Embellishment durability (e.g., pull-test for crystal adhesion) is also critical.

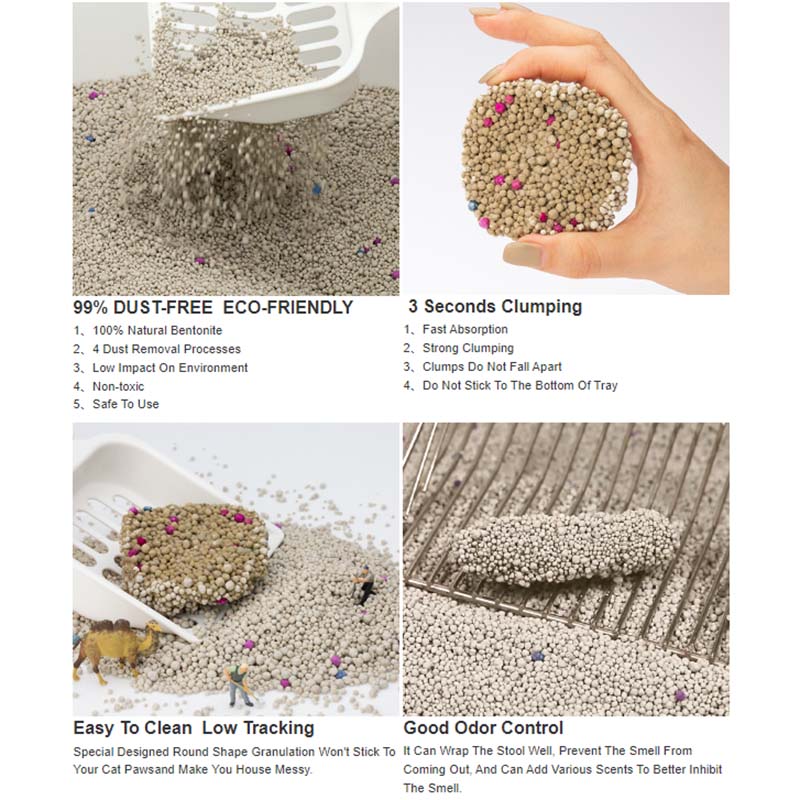

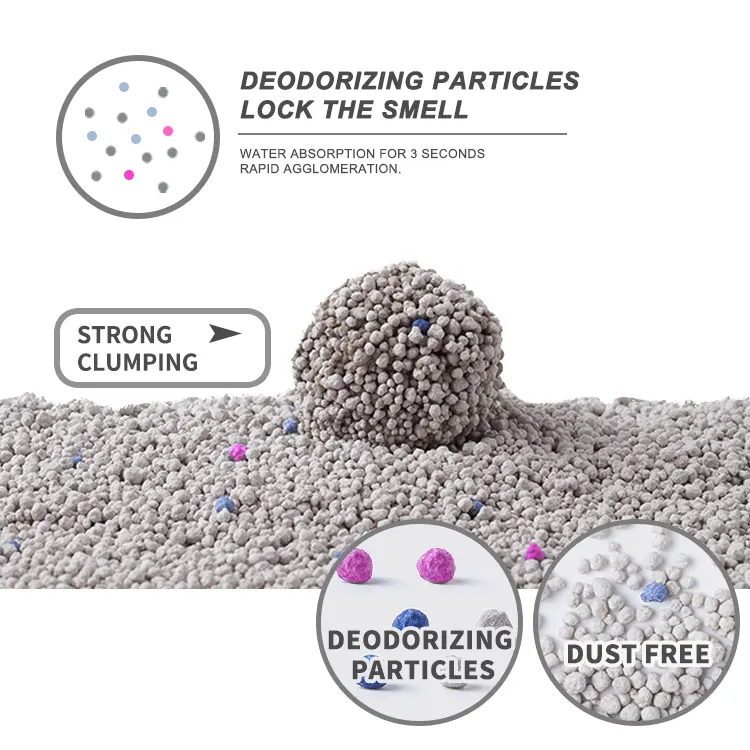

Beyond apparel, leading pet product manufacturers often boast diverse capabilities. For example, a manufacturer capable of high-precision apparel might also produce advanced pet hygiene products. Below are the specifications for a premium cat litter product, demonstrating the breadth of expertise:

Product Specification: China Factory 5L Dust Free Strong Clumping Bentonite Cat Litter

Image: Example of advanced pet hygiene products from a diversified manufacturer.

Application Scenarios & Technical Advantages

The output of a couture dog clothes factory finds its application in diverse high-value scenarios, reflecting the premium nature and technical advantages of the products.

- Luxury Pet Boutiques & High-End Retail: These garments are designed to command premium pricing, offering unique designs, superior comfort, and exceptional durability that mass-produced items cannot match. This enhances brand perception and customer loyalty for retailers.

- Pet Fashion Shows & Events: Custom-designed pieces for runway events, photography shoots, or special occasions where visual impact and fit are paramount. The technical advantage lies in the factory's ability to execute complex designs with precise tailoring and specialized embellishments.

- Celebrity Pet Endorsements & Brand Collaborations: Products must withstand public scrutiny and rigorous use while maintaining aesthetic appeal. The factory's adherence to stringent QC and use of robust, pet-safe materials ensures longevity and performance.

- Functional Luxury for Specific Climates: Development of specialized `fall clothes for dogs factory` collections or winter wear, featuring technical fabrics for insulation, water resistance, or breathability, provides genuine utility alongside style.

Beyond apparel, the capabilities often extend to other premium pet products. A `fresh & natural cat litter manufacturer` offers products with superior clumping, odor control, and dust-free properties, directly improving pet health and owner convenience—a clear technical advantage in the highly competitive pet hygiene market. The meticulous manufacturing for apparel translates into equally high standards for other pet essentials.

Vendor Comparison: Selecting Your Couture Pet Apparel Partner

Choosing the right manufacturing partner is crucial for luxury pet brands. A robust vendor comparison considers several critical factors beyond mere cost. A leading couture dog clothes factory distinguishes itself through demonstrated excellence in these areas.

Image: Meticulous fabric selection, a hallmark of a premier couture dog clothes factory.

Customized Solutions & Full-Service Partnerships

A true partner couture dog clothes factory offers comprehensive customized solutions, understanding that each brand has unique needs. This extends from initial concept to final delivery.

- Design & Development: Collaborative design process, custom pattern creation for various breeds and sizes, material consultation, and prototyping services. This includes specialized adaptations for `fall clothes for dogs factory` collections or specific event wear.

- Private Label & OEM/ODM: Full support for private label manufacturing, including custom branding, labels, tags, and packaging. Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services allow clients to either provide their designs or collaborate on new product development, leveraging the factory's in-house design capabilities.

- Material Customization: Sourcing of specific fabrics, unique color dyeing, custom prints, or embellishment techniques that align with a brand's aesthetic and functional requirements.

- Logistics & Fulfillment: Comprehensive support including international shipping, customs documentation, and inventory management, ensuring a seamless supply chain from factory floor to retail shelves.

The ability to provide these tailored solutions across a diverse product portfolio—from couture apparel to being a reliable `fresh & natural cat litter supplier`—underscores a manufacturer's flexibility and commitment to partnership.

Application Case Studies: Success in Luxury Pet Apparel

Real-world examples demonstrate the tangible impact of partnering with an expert couture dog clothes factory.

-

Case Study 1: "The Royal Canine Collection" Launch

A burgeoning luxury pet brand sought to launch a line of elaborate, historically-inspired dog costumes for high-end events. The chosen couture dog clothes factory provided end-to-end support, from material selection (silk brocades, velvet, hand-embroidered metallic threads) to complex pattern grading for various dog breeds (from Chihuahuas to Great Danes). Leveraging their advanced embellishment techniques and stringent QC, the factory delivered garments that exceeded client expectations in terms of detail, fit, and durability. The collection was featured in international pet fashion magazines, driving significant brand recognition and a 300% increase in initial sales forecasts.

-

Case Study 2: Seasonal Performance Wear for "Active Paws"

An activewear brand for pets approached the factory for a durable and stylish `fall clothes for dogs factory` collection. The challenge was to combine weather-resistant, breathable fabrics with ergonomic designs for active dogs. The factory's expertise in technical textile sourcing and precision stitching (flatlock seams, waterproof zippers) ensured garments offered optimal mobility, protection from elements, and comfort. Prototype testing confirmed excellent performance in various weather conditions. The collection was lauded by pet owners for its functionality and aesthetic, leading to repeat orders and expansion into a full year-round line.

Image: Example of luxurious pet apparel, a product of a dedicated couture dog clothes factory.

Trustworthiness: FAQs, Lead Times, Warranty & Support

Frequently Asked Questions (FAQ)

-

Q: What are your Minimum Order Quantity (MOQ) requirements for couture apparel?

A: MOQs for couture dog clothes factory items typically start from 100-300 units per design, depending on complexity and material. We offer flexibility for initial sample orders and custom projects.

-

Q: Can you handle unique or specialized materials?

A: Yes, our expertise lies in working with a wide range of premium and specialized fabrics, including silks, fine wools, technical synthetics, and sustainable options. Our sourcing team can also assist in acquiring specific materials.

-

Q: Do you offer design assistance for new collections?

A: Absolutely. Our in-house design and pattern engineering teams can provide full ODM services, helping translate your vision into manufacturable products, including developing new `fall clothes for dogs factory` styles.

-

Q: How do you ensure product safety for pets?

A: We prioritize pet safety through rigorous material selection (OEKO-TEX certified where applicable), pet-safe embellishments, and non-toxic dyes. All products undergo strict quality checks to ensure no choking hazards or harmful components.

-

Q: Can you also supply other pet products, like cat litter?

A: Yes, our manufacturing capabilities extend to a broad range of pet products. As a `fresh & natural cat litter manufacturer` and `fresh & natural cat litter supplier`, we offer high-quality bentonite cat litter with excellent clumping and odor control, maintaining the same high standards as our apparel.

Lead Time & Fulfillment Details

Standard lead times for custom couture dog apparel typically range from 30 to 60 days from final sample approval, depending on order volume and design complexity. This includes material sourcing, production, and initial quality checks. Express options may be available for urgent orders. We provide transparent timelines and regular updates throughout the production cycle, ensuring efficient global fulfillment and adherence to agreed-upon delivery schedules. For cat litter products, lead times are generally shorter, around 15-30 days, given established supply chains for raw materials.

Warranty Commitments

We stand behind the quality of products from our couture dog clothes factory. All garments come with a warranty against manufacturing defects for a period of 6 months from the date of shipment. This covers issues related to stitching, material flaws, or embellishment detachment under normal wear conditions. Specific terms and conditions apply and are detailed in our partnership agreements. Our commitment extends to all our products, including a guarantee of specified performance for our `fresh & natural cat litter`.

Customer Support Information

Clients are assigned a dedicated account manager who serves as a single point of contact for all inquiries, from design consultation to logistics. Our customer support team is available during business hours via email, phone, and video conferencing to provide prompt and expert assistance. We offer comprehensive after-sales support, including handling returns, addressing quality concerns, and facilitating reorders or new product development. Our technical support team also provides guidance on product specifications and industry standards.

Image: Dedicated customer support is integral to a leading couture dog clothes factory partnership.

Conclusion

The landscape of pet product manufacturing is increasingly sophisticated, with specialized facilities like a couture dog clothes factory setting new benchmarks for quality, design, and ethical production. By integrating advanced technologies, adhering to rigorous testing standards, and offering comprehensive customized solutions, these manufacturers enable brands to thrive in the competitive luxury pet market. Furthermore, the capacity to diversify into other essential pet products, such as becoming a reliable `fresh & natural cat litter manufacturer` or `fresh & natural cat litter supplier`, demonstrates a holistic approach to pet care manufacturing. For B2B decision-makers, partnering with such a versatile and quality-driven factory is not just a sourcing decision but a strategic investment in innovation, brand reputation, and long-term market leadership.

References

- Textile Industry Standards: ASTM International. (n.d.). ASTM Standards. Retrieved from www.astm.org

- Colorfastness Testing: AATCC. (n.d.). AATCC Test Methods. Retrieved from www.aatcc.org

- Textile Safety Certification: OEKO-TEX. (n.d.). OEKO-TEX Standard 100. Retrieved from www.oeko-tex.com

- Quality Management Systems: International Organization for Standardization. (n.d.). ISO 9001. Retrieved from www.iso.org

- Pet Industry Market Analysis: American Pet Products Association (APPA). (n.d.). Pet Industry Trends. Retrieved from www.americanpetproducts.org