- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

One-Stop China Sourcing Company | Streamlined Sourcing & Quality Control

Navigating Global Manufacturing: The Rise of Integrated Sourcing

In today's complex global supply chain, businesses across sectors from industrial manufacturing to consumer goods are continually seeking efficiencies without compromising quality or innovation. The demand for streamlined procurement, robust quality control, and timely delivery has led to the emergence of specialized partners capable of managing the entire production lifecycle. This critical need is precisely addressed by a proficient One-Stop China Sourcing Company. Such entities act as an indispensable bridge, connecting global enterprises with China's vast manufacturing ecosystem, simplifying operations, and mitigating the inherent risks of international trade and production.

Industry trends highlight a significant shift towards integrated sourcing models. The traditional fragmented approach, involving multiple vendors for different components or stages of production, is increasingly giving way to comprehensive solutions. This paradigm shift is driven by the imperative to reduce lead times, optimize costs, ensure material traceability, and maintain consistent product quality. Data from recent market analyses indicate that companies utilizing integrated sourcing services can achieve up to a 20% reduction in procurement costs and a 15% improvement in time-to-market for new products, primarily due to synchronized processes and reduced communication overheads. Furthermore, the emphasis on sustainability and ethical sourcing has elevated the role of these integrated partners, who are often responsible for auditing and ensuring compliance throughout the supply chain.

Comprehensive Sourcing streamlines global procurement processes.

The Integrated Manufacturing and Sourcing Process Flow

The operational framework of a leading One-Stop China Sourcing Company is meticulously structured to ensure efficiency, quality, and transparency from concept to delivery. This multi-stage process is designed to accommodate diverse product specifications and industry requirements, emphasizing robust quality control at every juncture.

1. Project Definition & Design

Initial client consultation, requirement analysis, DFM (Design for Manufacturability) review, material selection (e.g., SS304/316, ABS, PP, Silicone), CAD modeling, prototyping.

2. Supplier Qualification & Auditing

Identification of qualified manufacturers, factory audits (ISO 9001, SA8000), capacity assessment, cost negotiation, tooling development oversight.

3. Manufacturing & Production

Processes include casting (sand, die, investment), forging, CNC machining (milling, turning), injection molding (for plastics), stamping, welding, surface treatments (powder coating, anodizing).

4. Quality Assurance & Testing

In-line and final inspections, FAI (First Article Inspection), PPAP (Production Part Approval Process), adherence to standards like ISO, ANSI, ASTM, DIN. Testing for material composition, dimensions, functionality, durability.

5. Logistics & Delivery

Packaging optimization, warehousing, customs clearance, global shipping (FCL/LCL, air freight), last-mile delivery coordination.

Typical service life for components sourced through these processes can range from 5 to 50 years, depending on material, application, and environmental conditions. For instance, stainless steel components (e.g., for petrochemical or water supply systems) are designed for extreme corrosion resistance and longevity, often exceeding 20 years in service. Target industries benefiting from these comprehensive services include petrochemical, metallurgy, automotive, water supply & drainage, medical devices, consumer electronics, and general industrial machinery. In the petrochemical sector, precision-machined valves offer enhanced energy saving through optimized flow characteristics and superior corrosion resistance, reducing maintenance downtime.

The manufacturing process ensures adherence to global quality standards.

Technical Specifications and Capabilities

The technical prowess of a leading One-Stop China Sourcing Company lies in its deep understanding of various manufacturing disciplines and material sciences. This expertise allows for the precise execution of complex designs, catering to stringent technical parameters required by B2B clients.

Core Material & Process Capabilities:

| Category | Specifications/Parameters | Typical Applications |

|---|---|---|

| Metals | Stainless Steel (SS304, SS316, 17-4PH), Aluminum Alloys (6061, 7075), Brass, Copper, Carbon Steel, Alloy Steel. Machining tolerance down to ±0.005mm. Surface finishes Ra 0.8-3.2. | Automotive components, medical instruments, industrial valves, electronic housings, consumer durables. |

| Plastics & Composites | ABS, PP, PE, PC, Nylon, POM, PEEK, Silicone. Injection molding, extrusion, compression molding. Component weight range from 0.1g to 5kg. | Enclosures, gears, insulators, seals, consumer product parts (e.g., pet water bottle lids), food-grade container111s. |

| Manufacturing Processes | CNC Machining (3-axis, 5-axis), Die Casting (Zinc, Aluminum), Investment Casting, Sand Casting, Forging, Stamping, Injection Molding, Laser Cutting, Welding. | High-precision parts, complex geometries, high-volume production, structural components. |

| Quality Control & Certifications | ISO 9001:2015 certified manufacturers, PPAP Level 3, FAI, CMM dimensional inspection, Spectrometer material analysis, RoHS/REACH compliance. | Ensuring product integrity, compliance with international standards, critical safety applications. |

Parameter control is paramount. For example, in CNC machining, critical dimensions are often held to IT6-IT7 tolerances, essential for mating parts in complex assemblies. Surface roughness (Ra) is managed based on functional requirements, with Ra 0.8 being common for precision bearing surfaces, ensuring optimal friction and wear characteristics. Material properties, such as tensile strength (e.g., 500-700 MPa for SS304) and yield strength, are rigorously tested to ensure performance under specified loads and environmental conditions.

Precision engineering is a cornerstone of effective sourcing.

Application Scenarios and Technical Advantages

The versatility of a specialized One-Stop China Sourcing Company extends its impact across a myriad of industrial and consumer applications, offering distinct technical advantages.

Diverse Application Scenarios:

-

✓

Petrochemical Industry: Sourcing of specialized valves, fittings, and pipeline components in corrosion-resistant alloys. Ensures compliance with API and ASME standards, critical for preventing catastrophic failures and maintaining operational continuity in harsh environments.

-

✓

Metallurgy: Procurement of high-temperature resistant parts, molds, and precision castings. These components often require specific heat treatments and material compositions to withstand extreme thermal cycling and abrasive conditions in smelting and refining processes.

-

✓

Water Supply & Drainage: Sourcing of large-diameter pipes, pumps, filtration system components, and robust connectors. Focus on materials that resist biofouling and chemical degradation, ensuring long service life and public health safety.

-

✓

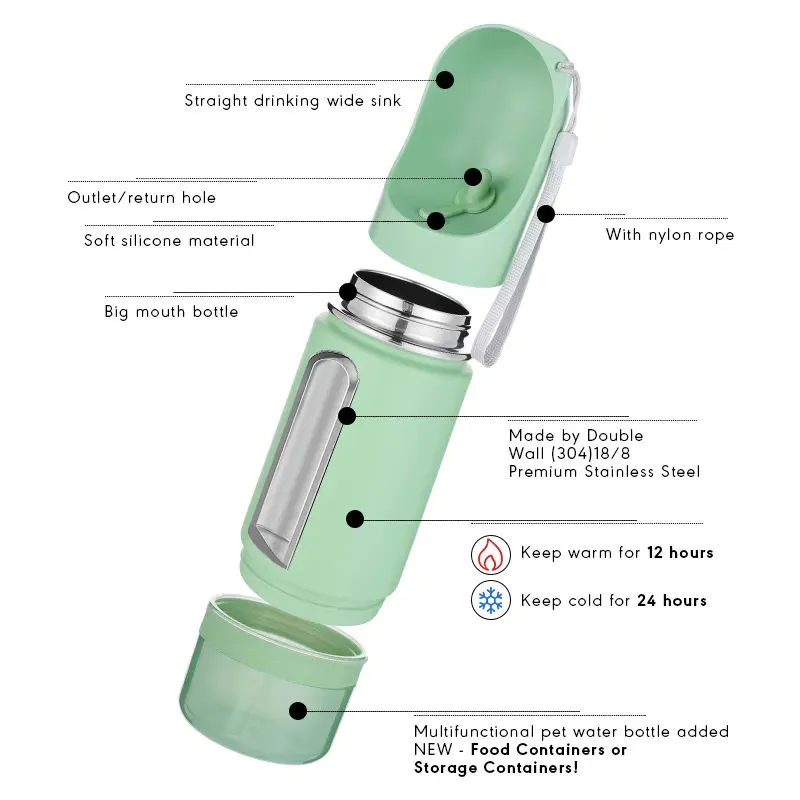

Consumer Goods (e.g., Pet Products): Sourcing multi-material assemblies like the Areeman Travel 18oz dog water bottle. This involves procuring food-grade stainless steel for the bottle, BPA-free plastics (ABS, PP) for the lid and integrated food storage, and silicone for seals. Technical advantages include ensuring compliance with FDA/LFGB standards, achieving complex part geometries through advanced injection molding, and managing multi-vendor assembly.

Key Technical Advantages:

- Optimized Energy Saving: Through advanced manufacturing techniques and material selection, components are designed for reduced friction, better thermal management, and improved system efficiency. For example, in pump impellers, optimized flow paths can lead to a 5-10% reduction in energy consumption.

- Superior Corrosion Resistance: Strategic material selection (e.g., Duplex Stainless Steels, Hastelloy) and advanced surface treatments provide extended product life in aggressive chemical or marine environments, drastically cutting replacement costs.

- Precision Engineering: Access to high-precision CNC machining and tooling capabilities ensures components meet exact specifications, critical for seamless integration into complex machinery and systems.

- Scalability & Flexibility: Ability to manage production runs from low-volume prototyping to high-volume mass production, adapting to evolving market demands without significant retooling delays.

- Cost-Efficiency without Compromise: Leveraging China's competitive manufacturing landscape combined with rigorous quality oversight ensures cost advantages without sacrificing material integrity or functional performance.

Versatile applications from industrial to consumer products are supported.

Vendor Comparison: One-Stop Sourcing vs. Traditional Methods

Choosing the right sourcing strategy is pivotal for business success. A detailed comparison illustrates the distinct advantages a One-Stop China Sourcing Company offers over conventional multi-vendor or direct sourcing approaches.

| Feature | One-Stop China Sourcing Company | Traditional Multi-Vendor Sourcing | Direct Factory Sourcing (DIY) |

|---|---|---|---|

| Project Management | Centralized, single point of contact. End-to-end oversight, DFM, QA, logistics. | Dispersed, client manages multiple vendor relationships. Complex coordination. | Client manages all aspects, including factory communication, quality, and shipping. |

| Quality Control (QC) | Integrated QC protocols, in-line inspections, third-party certifications (ISO, SGS). Proactive issue resolution. | QC varies by vendor. Client often needs separate inspection services. Reactive issue handling. | Client responsible for establishing and enforcing QC, often requires on-site presence. |

| Cost Efficiency | Optimized through consolidated purchasing power, reduced operational overheads, and efficient logistics. Transparent pricing. | Hidden costs in coordination, separate shipping, higher risk of quality issues leading to rework. | Potentially lowest unit cost but high indirect costs in time, travel, and risk management. |

| Risk Mitigation | Experienced team manages supplier reliability, quality deviations, intellectual property protection, and logistics disruptions. | Higher exposure to individual supplier failures, quality inconsistencies, and communication breakdowns. | Client bears full risk of factory fraud, quality issues, shipping delays, and legal disputes. |

| Lead Time & Speed-to-Market | Streamlined processes, expedited sampling, and efficient production scheduling accelerate delivery. | Often extended due to coordination challenges between multiple parties and potential delays. | Can be slow due to learning curve, language barriers, and lack of established relationships. |

The clear operational and financial benefits underscore why integrated sourcing is becoming the preferred model for discerning B2B enterprises. It shifts the burden of managing intricate supply chain complexities from the client to an expert partner, allowing clients to focus on core competencies like R&D, marketing, and sales.

Customized Solutions and Application Case Studies

A hallmark of a truly valuable One-Stop China Sourcing Company is its ability to offer highly customized solutions, moving beyond off-the-shelf products to bespoke manufacturing and supply chain strategies.

Tailored Solutions:

-

★

Product Design & Engineering: Collaborating on DFM (Design for Manufacturability) and DFA (Design for Assembly) to optimize existing designs for cost-effective mass production while maintaining performance integrity.

-

★

Material Sourcing & Development: Identifying alternative materials that meet performance requirements while offering cost advantages or improved sustainability profiles. This includes specialized alloys, engineering plastics, or composites.

-

★

Tooling & Prototyping: Managing the entire tooling process, from mold design and fabrication to rapid prototyping, ensuring initial samples accurately reflect production intent.

-

★

Private Labeling & Packaging: Developing custom branding, packaging design, and retail-ready solutions tailored to specific market demands and brand guidelines.

Application Case Study: High-Performance Pet Hydration System

A prominent pet product brand sought to develop an innovative, multi-functional pet water bottle, similar to the Areeman Travel 18oz dog water bottle. Their vision was a durable, portable, and hygienic solution for pet owners on the go, integrating water and food storage in a single unit. The challenge involved sourcing specific food-grade materials, ensuring leak-proof design, and managing assembly of diverse components from multiple sub-suppliers.

Integrated solutions for complex consumer products like pet accessories.

-

●

Client Objective: Launch a premium, durable, and safe 3-in-1 pet water, food, and waste bag dispenser bottle within a 6-month timeframe.

-

●

Solution by the One-Stop Sourcing Company:

- Material Selection: Sourced certified food-grade 304 stainless steel for the bottle body and BPA-free ABS/PP plastics for the lid and internal components, ensuring compliance with FDA and LFGB standards.

- Manufacturing Oversight: Managed multi-vendor production, including deep-drawing for the stainless steel bottle, precision injection molding for the intricate lid mechanism and food compartment, and silicone gasket molding for leak-proof seals.

- Quality Assurance: Implemented a staged QC process, including material incoming inspection, in-line checks during each manufacturing step, and final product functional testing (e.g., leak tests, drop tests, material safety analysis).

- Logistics Integration: Consolidated components from various factories, managed final assembly, custom packaging, and direct shipping to the client's distribution centers in Europe and North America.

-

●

Outcome: The client successfully launched the product on schedule, exceeding initial quality expectations. The integrated approach saved the client an estimated 25% in overall project costs compared to managing individual suppliers and reduced the project timeline by approximately 2 months, leading to a strong market entry.

This case exemplifies how a comprehensive One-Stop China Sourcing Company manages complex product development and manufacturing challenges, delivering high-quality, market-ready products efficiently and effectively.

Commitment to Trustworthiness: FAQ, Lead Times, Warranty, and Support

Building and maintaining trust is paramount in B2B partnerships. A reputable One-Stop China Sourcing Company backs its services with clear commitments to transparency, reliability, and robust support.

Frequently Asked Questions (FAQ):

What industries do you specialize in?

We serve a broad range of industries, including petrochemical, metallurgy, water supply & drainage, automotive, consumer goods, electronics, and medical devices, leveraging our extensive network of specialized manufacturers.

How do you ensure product quality?

Our multi-stage quality control system includes factory audits, in-line production inspections, pre-shipment inspections, material testing, and compliance with international standards such as ISO 9001, ANSI, ASTM, and client-specific requirements like PPAP.

Can you handle intellectual property (IP) protection?

Yes, IP protection is a critical component of our service. We implement Non-Disclosure Agreements (NDAs) with all relevant partners and utilize secure data transfer protocols. Our audited factories understand and respect IP rights, safeguarding your designs and proprietary information.

What is your process for new product development?

We offer comprehensive NPI (New Product Introduction) services, starting from DFM consultation, prototyping, tooling development, sample validation, pilot production, and finally, mass production. We guide you through each step to ensure your vision becomes a market-ready product.

Lead Time & Fulfillment Details:

Lead times are project-specific and depend on complexity, material availability, and order volume.

- Prototyping: Typically 2-4 weeks for initial samples after design finalization.

- Tooling Development: 4-8 weeks, depending on mold complexity (e.g., for injection molding or die casting).

- Mass Production: Standard lead times range from 4-8 weeks from order confirmation and deposit, varying with material procurement and factory scheduling. Rush orders can be accommodated based on capacity.

- Logistics: Sea freight typically takes 3-5 weeks to major global ports; air freight 5-10 days. Expedited shipping options are available.

Transparency in operations builds lasting client relationships.

Warranty Commitments:

We stand by the quality of products sourced through our network. All products come with a standard 1-year warranty against manufacturing defects, unless otherwise specified for custom projects. Extended warranties and service agreements can be negotiated based on product type and application. Our commitment includes:

- Defective product replacement or credit for confirmed manufacturing flaws.

- Full traceability of materials and production batches for quality accountability.

- Adherence to mutually agreed-upon quality standards and specifications outlined in the PO.

Customer Support Information:

Our dedicated project management teams provide continuous support throughout the sourcing journey and beyond.

- Dedicated Account Manager: A single point of contact for all inquiries, updates, and issue resolution.

- 24/7 Online Portal: Access to real-time production updates, documentation, and communication logs.

- Technical Assistance: Post-delivery technical support for product integration or performance queries.

- Global Reach: Support teams operating across different time zones to ensure timely responses.

Our goal is to foster long-term partnerships built on consistent performance and reliable service, making us your trusted extension in China.

Conclusion

In an era defined by global interconnectivity and market demands for innovation and efficiency, the strategic value of a One-Stop China Sourcing Company cannot be overstated. By consolidating complex supply chain functions, ensuring stringent quality control, and offering bespoke manufacturing solutions, these specialized entities empower B2B enterprises to navigate the intricacies of international production with confidence and strategic advantage. The comprehensive approach to material sourcing, manufacturing oversight, and logistical management translates directly into reduced operational costs, accelerated market entry, and superior product quality, solidifying China's role as a powerhouse in global manufacturing, effectively managed by expert partners.

References:

- Council of Supply Chain Management Professionals. (2023). State of Logistics Report.

- International Organization for Standardization. (2022). ISO 9001: Quality Management Systems.

- Journal of Global Operations and Strategic Sourcing. (2021). The Impact of Integrated Sourcing on Supply Chain Resilience.

- Pet Industry Global Market Insights. (2023). Consumer Trends in Pet Accessories and Durables.

- ANSI/ASME Standards & Practices for Manufacturing and Engineering. (Latest Revisions).