- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

One-Stop China Sourcing Company: Simplify Your Global Supply Chain

Strategic Sourcing Excellence: The Value Proposition of a One-Stop China Sourcing Company

In an era defined by globalized markets and intricate supply chains, B2B entities are continually seeking robust, agile, and cost-efficient solutions for their manufacturing and procurement needs. A premier One-Stop China Sourcing Company represents a transformative approach, offering an integrated suite of services that spans the entire product lifecycle from initial design to final delivery. This model significantly de-risks international sourcing, providing a consolidated channel for supplier identification, quality assurance, logistics management, and regulatory compliance.

The intrinsic value of such a partnership lies in its capability to leverage China's unparalleled manufacturing ecosystem while circumventing the common pitfalls associated with direct overseas engagements. These include language barriers, cultural misunderstandings, intricate quality control challenges, and complex logistical arrangements. By acting as a single point of accountability, a comprehensive sourcing partner empowers businesses to optimize their capital expenditure, accelerate time-to-market, and uphold stringent quality benchmarks across diverse product portfolios.

Operational Process Flow: Precision in Every Stage

The operational framework of a leading One-Stop China Sourcing Company is meticulously structured to ensure end-to-end transparency, quality, and efficiency. Each phase is managed by expert teams, adhering to global best practices and industry-specific standards.

Integrated Sourcing Process Overview

-

1. Client Consultation & Detailed Requirements Scrutiny:

In-depth analysis of client's product specifications, including CAD drawings, material requirements (e.g., specific grades of 304/316L stainless steel, engineering plastics like PC/ABS, or specialty alloys), functional performance criteria, critical tolerances, and projected volumes. This stage defines the scope and forms the basis for supplier selection.

-

2. Qualified Vendor Identification & Audit:

Leveraging an expansive, vetted network of manufacturers. Comprehensive factory audits assess production capabilities (e.g., CNC machining, die casting, injection molding, forging capacity), quality management systems (e.g., ISO 9001:2015, IATF 16949 for automotive), ethical labor practices, and financial stability. Emphasis is placed on suppliers with proven expertise in specific materials and processes.

-

3. Prototyping, Tooling Development & Sample Validation:

Collaborative design for manufacturability (DFM) analysis. Creation of prototypes using additive manufacturing (3D printing) or traditional methods. Tooling design and fabrication are managed to optimize for longevity and precision. Samples undergo rigorous testing to ensure compliance with all specified parameters and client approval before mass production.

-

4. Production Management & In-Process Quality Control:

Constant monitoring of production lines. This includes material incoming inspection (IQC), in-process quality control (IPQC) at critical manufacturing stages such as casting, forging, CNC machining, welding, and assembly. Parameters like surface finish (Ra value), dimensional accuracy, mechanical properties (tensile strength, hardness), and leak testing are continuously checked against standards like ASTM, ANSI, or JIS.

-

5. Final Quality Assurance (FQA) & Third-Party Inspection:

Pre-shipment inspection (PSI) conducted by independent or dedicated QC teams. This comprehensive audit ensures that finished products meet all technical, aesthetic, and packaging specifications. Compliance with product-specific certifications (e.g., CE, RoHS, FDA for food contact, REACH) is verified, often with external lab testing.

-

6. Packaging Optimization & Logistics Coordination:

Designing packaging for product protection during transit and retail presentation. Consolidation of cargo for optimized freight costs. Handling all export documentation, customs clearance procedures, and coordination with reputable shipping lines or air cargo carriers for global door-to-door delivery.

-

7. Post-Delivery Support & Continuous Improvement:

Ongoing client support, addressing any unforeseen issues, and collecting feedback for supplier performance evaluation and process refinement. This iterative loop ensures long-term partnerships and continuous improvement in service and product quality.

The service life of sourced components is a critical metric. For high-wear industrial parts like specialized bearings or seals, projected service life can be 5-10 years, contingent on operational conditions and maintenance, with materials like high-performance polymers or hardened tool steels. For general consumer goods, a target service life of 2-5 years under normal usage conditions is typically aimed for, utilizing durable plastics and corrosion-resistant metals.

This comprehensive process benefits various target industries by delivering advantages such as energy saving, enhanced corrosion resistance, and reduced total cost of ownership (TCO):

- Petrochemical: Sourcing of API 600 series valves, flanges, and high-pressure piping components made from exotic alloys (e.g., Hastelloy, Inconel) for severe corrosion resistance and extreme temperature applications. Ensuring compliance with NACE MR0175 for sour service and ISO 15156.

- Metallurgy & Heavy Industry: Procurement of large-scale precision castings, forged shafts, and wear-resistant components from specialized tool steels (e.g., D2, H13) for mining equipment, steel mills, and heavy machinery. Focus on material integrity and fatigue life.

- Water Supply & Drainage Systems: Sourcing of energy-efficient pumps, ductile iron pipes, and precise control valves meeting AWWA standards. Emphasis on robust sealing mechanisms, long-term corrosion resistance for potable water, and minimized pressure loss for energy saving.

- Medical Devices: Precision machining of biocompatible materials (e.g., medical-grade titanium, PEEK) for surgical instruments and implantable components, adhering to ISO 13485 standards and FDA regulations.

- Consumer Electronics: From intricate PCBs to durable plastic enclosures and precision metal parts, ensuring compliance with CE, FCC, and RoHS directives, alongside rigorous reliability testing.

Google Compliance: Expertise, Experience, Authoritativeness, and Trustworthiness

Expertise: Mastering Technical Nuances

A leading One-Stop China Sourcing Company exhibits profound technical expertise across diverse engineering disciplines. This includes a deep understanding of metallurgy, enabling precise selection of alloys for specific applications – for example, selecting 430 stainless steel for magnetic requirements or 316L for enhanced corrosion resistance in marine environments. Their proficiency extends to polymer science, advising on the optimal plastic resins (e.g., high-density polyethylene for chemical resistance, polycarbonate for impact strength) for injection molding, extrusion, or blow molding processes. Furthermore, they are adept in advanced manufacturing techniques such as wire EDM for intricate cuts, ultrasonic welding for plastic assembly, and specialized surface treatments like anodizing, powder coating, or electropolishing to achieve desired aesthetic, protective, and functional properties, including specific roughness average (Ra) values.

Experience: Proven Success in Complex Sourcing Scenarios

The practical experience garnered by an established One-Stop China Sourcing Company is invaluable. This includes navigating the complexities of producing intricate medical device prototypes that demand sterile manufacturing environments and Class 100,000 cleanroom compliance, or mass-producing high-volume consumer goods under strict budgetary constraints. Their portfolio reflects successful projects ranging from heavy industrial machinery parts requiring advanced non-destructive testing (NDT) to delicate electronic components necessitating electrostatic discharge (ESD) protection. Client testimonials frequently highlight the sourcing partner's ability to foresee and mitigate potential production issues, deliver consistent quality, and manage unexpected supply chain fluctuations, ensuring minimal disruption and maximum client satisfaction.

Authoritativeness: Certifications, Partnerships, and Data-Driven Quality

Authoritativeness is established through transparent adherence to recognized international standards and a verifiable history of successful collaborations. This typically includes:

- Rigorous Certifications: Partner factories frequently hold ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), SA8000 (Social Accountability), and product-specific certifications like CE, RoHS, FCC, and FDA compliance (where applicable).

- Years of Service: Many reputable sourcing firms have been operating for well over 10-15 years, cultivating extensive networks and deep market intelligence.

- Prestigious Partnerships: While specific client names remain confidential, a strong portfolio will indicate partnerships with globally recognized brands or major industry players.

- Authoritative Standards: Compliance with international material standards (ASTM, EN, DIN, GB), testing protocols (e.g., destructive/non-destructive testing, fatigue testing), and environmental regulations.

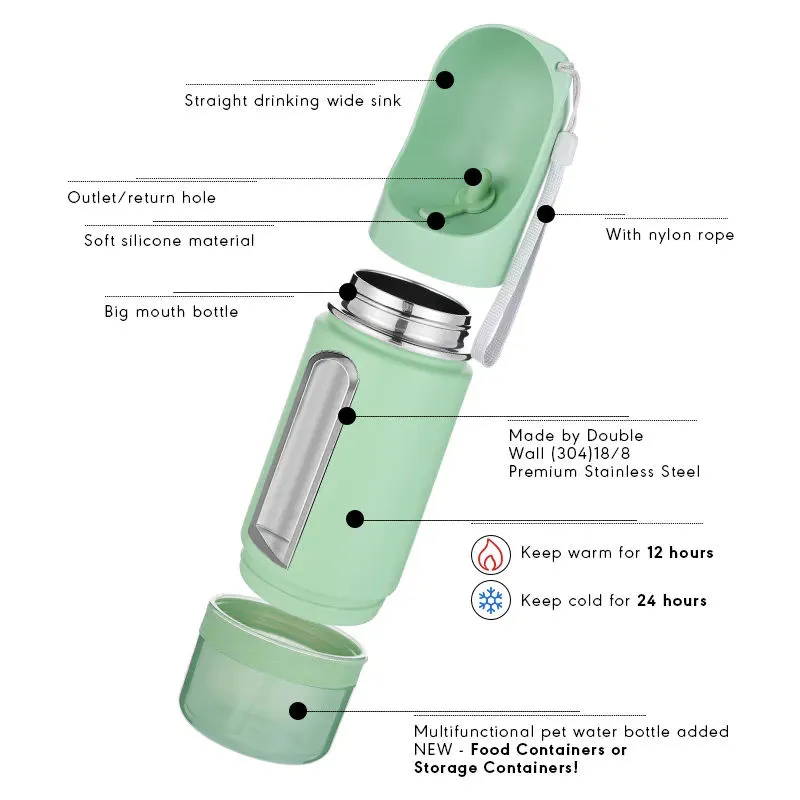

Data-Driven Example: New Design Mini Portable 14oz Stainless Steel Dog Water Bottle Specifications

| Parameter | Specification Detail | Relevant Standard / Certification |

|---|---|---|

| Product Model | Mini Portable Travel Dog Water Bottle | N/A |

| Material (Bottle Body) | Food-grade 304 Stainless Steel (0.5mm wall thickness) | FDA 21 CFR 177.2600, LFGB, EN 10088-1 (for steel grade) |

| Material (Drinking Trough/Lid) | BPA-free ABS Plastic | FDA 21 CFR 177.1010, LFGB, REACH, RoHS 2.0 |

| Seal Material | Food-grade Silicone (high-temperature vulcanized) | FDA 21 CFR 177.2600, EN 14350 |

| Capacity | 14oz / 400ml | ISO 7086-1 (volume measurement) |

| Leak-Proof Mechanism | One-button open/lock, internal silicone gasket, water recirculation | IPX7 (simulated submersion for 30 min at 1m depth) |

| Thermal Insulation | Single-wall design (not insulated) | N/A |

| Durability (Drop Test) | Withstands drops from 1.5 meters onto hard surfaces (full capacity) | ASTM D523-14 (modified) |

| Weight (Empty) | ~250g | Precision laboratory scale (NIST traceable) |

| Color Options | Customizable via Pantone match | Pantone Color Matching System |

Trustworthiness: Transparency, Guarantees, and Responsive Support

Building trustworthiness is fundamental for long-term B2B partnerships. A reliable sourcing company ensures this through:

- Transparent Pricing & Cost Analysis: Detailed quotes outlining unit costs, tooling, logistics, customs duties, and QC fees, ensuring no hidden charges.

- Predictable Lead Times & Fulfillment: Typical prototyping lead times are 2-4 weeks. Mass production cycles range from 4-8 weeks, influenced by product complexity, order volume, and material availability. Expedited air freight for urgent orders and optimized sea freight for cost-effectiveness are standard options.

- Comprehensive Warranty Commitments: A standard 1-year warranty against manufacturing defects in materials and workmanship is typically provided. Extended warranties or specific performance guarantees can be negotiated for large-scale projects or critical components.

- Dedicated Customer Support: A dedicated project manager serves as the primary contact, providing regular updates, addressing queries promptly, and offering support through various channels (email, phone, video conferencing) across different time zones. Post-delivery issue resolution is a priority.

Industry Trends & Market Outlook

The global sourcing landscape is dynamic, with several critical trends shaping the operations and strategies of a One-Stop China Sourcing Company:

- Enhanced Supply Chain Resilience: Post-pandemic, there's an intensified focus on multi-regional sourcing, buffer inventory, and robust risk management protocols to mitigate disruptions. Diversification beyond a single geographic region is increasingly prioritized.

- Sustainability and Ethical Sourcing (ESG): Growing demand for environmentally friendly materials, energy-efficient production, and ethically compliant labor practices. Sourcing companies are expected to provide verifiable data on their suppliers' ESG performance.

- Digital Transformation & AI Integration: Adoption of AI-driven predictive analytics for demand forecasting, IoT sensors for real-time factory monitoring, and blockchain for supply chain traceability, enhancing efficiency and transparency.

- Customization at Scale: The market is moving towards personalized products and smaller, more frequent batches. Sourcing partners must offer flexibility in production volumes and custom engineering support.

- Automation and Smart Manufacturing: Increased adoption of robotic process automation (RPA) and advanced manufacturing techniques in partner factories to improve precision, reduce labor costs, and enhance production consistency.

Technical Advantages: Unlocking Manufacturing Excellence

Partnering with a One-Stop China Sourcing Company offers distinct technical advantages critical for complex B2B products:

- Material Science Expertise: Access to a vast array of specialized materials, from high-performance thermoplastics (e.g., PEEK, PTFE) for aerospace applications to advanced ceramics for high-temperature resistance, all with detailed material certificates (MTCs) and testing.

- Precision Manufacturing Capabilities: Oversight of factories equipped with state-of-the-art machinery, including 5-axis CNC machines for complex geometries, laser cutting and welding for fine details, and automated assembly lines for high consistency and reduced human error.

- Integrated Quality Engineering: Implementation of robust Quality Control (QC) frameworks including Statistical Process Control (SPC), Failure Mode and Effects Analysis (FMEA), and advanced metrology tools such as Coordinate Measuring Machines (CMMs) for sub-micron accuracy verification and optical comparators.

- Design for Manufacturability (DFM) & Assembly (DFA): Providing expert input during the design phase to optimize products for efficient and cost-effective manufacturing, minimizing potential production bottlenecks and ensuring ease of assembly.

- Scalability & Flexibility: Ability to adapt production scales from low-volume, high-mix orders to high-volume, low-mix orders without compromising quality or lead times. This flexibility is crucial for market entry strategies and rapid demand fluctuations.

Vendor Comparison: Integrated Sourcing vs. Traditional Models

Choosing the right sourcing strategy is pivotal. Below is a comparative analysis between engaging a One-Stop China Sourcing Company and traditional, fragmented sourcing methods:

| Aspect | One-Stop China Sourcing Company | Traditional Multi-Vendor/Direct Sourcing |

|---|---|---|

| Management Overhead | Minimal; single point of contact, consolidated project management, reduced internal resource allocation. | High; managing multiple suppliers, complex communication, significant internal team effort required. |

| Quality Assurance | Integrated, multi-stage QC (IQC, IPQC, FQA) by expert teams; adherence to global standards (ISO, ASTM, etc.). | Fragmented; client must implement/manage QC for each vendor, potential for inconsistent quality. |

| Logistics Complexity | Simplified; consolidated shipments, managed customs, optimized freight routes, door-to-door service. | High; individual shipments, complex customs coordination, potential for fragmented deliveries and higher costs. |

| Risk Mitigation | Proactive risk assessment, vetted suppliers, strong IP protection, financial guarantees from sourcing partner. | Client assumes primary risk; vulnerable to individual factory failures, potential IP vulnerabilities. |

| Cost Efficiency | Optimized total cost of ownership (TCO) through bulk purchasing, process efficiency, reduced hidden costs. | Lower unit costs possible, but often offset by higher costs in QC, logistics, and management time. |

| Speed to Market | Accelerated due to streamlined communication, coordinated production schedules, efficient problem-solving. | Can be slower due to coordination delays, separate prototyping/tooling for each vendor, communication gaps. |

Customized Solutions & Illustrative Case Studies

Tailoring Solutions to Exact Client Requirements

The strength of a sophisticated One-Stop China Sourcing Company lies in its ability to deliver highly customized solutions, moving beyond off-the-shelf procurement. This encompasses:

- Bespoke Design & Engineering Support: Offering extensive R&D collaboration, assisting with product redesign for cost reduction (Design to Cost) or performance enhancement (Design to Performance), and providing expert advice on material alternatives or process optimization.

- Specialized Material Procurement: Sourcing rare earth elements, specific polymer blends with unique additives (e.g., UV stabilizers, flame retardants), or niche metal alloys for advanced applications requiring specific mechanical, thermal, or electrical properties.

- Complex Assembly & Integration: Managing multi-part assemblies, integrating electronic components (PCBA), and performing specialized testing (e.g., burn-in testing for electronics, pressure testing for hydraulic systems) to deliver a ready-to-market product.

- Regulatory Compliance Navigation: Proactively identifying and ensuring compliance with a myriad of international standards specific to the target market and product category, including CE marking, UL certification, CSA, PSE, and specific environmental directives.

Application Case Studies

Case Study 1: Automotive OEM - Precision Aluminum Castings

A Tier 1 automotive supplier required lightweight, high-strength aluminum alloy castings for a new electric vehicle platform. The One-Stop China Sourcing Company identified a specialized foundry capable of producing vacuum die castings with advanced heat treatment, achieving strict porosity limits (less than 2% by X-ray) and precise dimensional tolerances (ISO 2768-m). They oversaw the entire process from mold design validation, alloy composition verification via spectrometry, to final CMM inspection and TUV certification, leading to a 20% cost saving on unit price and a 15% reduction in overall lead time compared to previous suppliers, while maintaining IATF 16949 quality standards.

Case Study 2: Consumer Goods Innovator - Eco-Friendly Packaging Solutions

A sustainable consumer brand aimed to switch to fully recyclable and compostable packaging for their product line. The sourcing partner developed custom molded fiber pulp packaging for delicate items and sourced biodegradable plastic films for flexible packaging. This involved identifying factories with specific certifications (e.g., BPI compostable, FSC for paper pulp), conducting extensive material degradation testing, and optimizing packaging design to withstand international shipping. The initiative resulted in the brand achieving its 100% sustainable packaging goal, improving brand perception, and reducing environmental footprint, all managed with seamless integration and consistent supply chain delivery.

Frequently Asked Questions (FAQ)

Q: How does a One-Stop China Sourcing Company manage supply chain risks?

A: Risk management involves a multi-pronged approach: rigorous supplier vetting and continuous monitoring, maintaining a diversified supplier base to avoid single points of failure, implementing clear contractual agreements with performance penalties, proactive geopolitical and economic trend analysis, and establishing contingency plans for logistics and production. Real-time communication and transparent reporting are crucial.

Q: What specific measures are taken for intellectual property (IP) protection?

A: IP protection is paramount. This includes signing comprehensive Non-Disclosure Agreements (NDAs) and Non-Circumvention, Non-Disclosure, and Non-Compete Agreements (NCNDAs) with all relevant parties (factories, tool makers, etc.), using trusted and audited factories known for IP integrity, securing patents and trademarks in China on behalf of clients, and managing tooling ownership/transfer directly to prevent unauthorized use.

Q: Can a sourcing company assist with design and engineering modifications?

A: Yes, many offer extensive design and engineering support. This includes providing DFM (Design for Manufacturability) feedback to optimize designs for efficient mass production, suggesting alternative materials for cost savings or improved performance, and assisting with CAD model refinement, prototyping, and tooling design to meet specific technical and budgetary goals.

Q: How are payment terms typically structured?

A: Standard payment terms usually involve a deposit (e.g., 30-50%) upon order confirmation to cover material and tooling costs, followed by the balance payment upon successful pre-shipment inspection (PSI) and before shipment. For long-term partners or large projects, more flexible payment schedules or Letter of Credit (L/C) arrangements can be negotiated.

Conclusion: The Indispensable Role of Integrated Sourcing in B2B Procurement

The decision to partner with a One-Stop China Sourcing Company represents a strategic investment in efficiency, quality, and competitive advantage. In an increasingly complex global trade environment, these integrated service providers offer more than just procurement; they offer a managed extension of a client's own supply chain. By meticulously handling every facet from engineering consultation and supplier validation to rigorous quality control and global logistics, they enable B2B enterprises to access China's vast manufacturing capabilities without the associated operational burdens and risks. The outcome is not merely cost savings, but enhanced product quality, accelerated market entry, and the strategic freedom to focus on core business development and innovation.

References

- International Organization for Standardization. (2023). ISO 9001:2015 - Quality management systems - Requirements.

- U.S. Food and Drug Administration. (2023). Code of Federal Regulations Title 21 - Food and Drugs.

- ASTM International. (2023). Annual Book of ASTM Standards.

- Institute for Supply Management. (2023). Manufacturing PMI Report.

- Supply Chain Management Review. (2022). The Resilient Supply Chain: Reimagining Global Sourcing.

- World Economic Forum. (2023). Future of Advanced Manufacturing and Production.