- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Couture Dog Clothes Factory | Luxury & Bespoke Pet Apparel Wholesale

Elevating Pet Apparel Manufacturing with Precision and Innovation

In the rapidly expanding pet industry, the demand for high-quality, aesthetically pleasing, and functional pet apparel has surged. A leading couture dog clothes factory is at the forefront of this evolution, blending sophisticated design with advanced manufacturing techniques to produce exceptional garments for canine companions. This commitment extends beyond apparel, reflecting a broader expertise in diverse pet product manufacturing, including essential consumables. This article delves into the intricate processes, technical advantages, and comprehensive capabilities that define a modern pet product manufacturing facility, providing insights for B2B decision-makers seeking reliable and innovative partners.

Our focus is on the precision and quality inherent in luxury pet garment production, while also showcasing the versatility required to excel as a fresh & natural cat litter manufacturer and supplier. This dual expertise underscores a holistic approach to pet care product development, ensuring every item, from an intricately designed dog jacket to a 5L bag of dust-free bentonite cat litter, meets stringent quality and performance benchmarks.

Industry Trends in High-End Pet Apparel

The global pet apparel market is experiencing robust growth, driven by the increasing humanization of pets and a rising disposable income among pet owners. Market analysis projects a CAGR of over 5% for the pet apparel market in the coming years, indicating a strong demand for premium and specialized products. Key trends influencing the sector include:

- Sustainable Materials: A growing preference for eco-friendly, organic, and recycled fabrics, aligning with consumer values for environmental responsibility.

- Smart Apparel: Integration of technology such as GPS trackers, temperature sensors, and health monitoring features into pet clothing.

- Customization and Personalization: Demand for bespoke designs, tailored fits, and personalized embellishments.

- Functional and Seasonal Wear: High-performance garments for specific weather conditions, including robust fall clothes for dogs factory output designed for warmth, water resistance, and visibility.

- Luxury and Designer Collections: Pets as fashion statements, leading to collaborations with renowned designers and the establishment of luxury brands in pet fashion.

These trends necessitate manufacturing partners who possess advanced capabilities, precision engineering, and a deep understanding of textile science, which are hallmarks of a reputable couture dog clothes factory.

The Advanced Manufacturing Process at a Couture Dog Clothes Factory

Producing high-quality pet apparel demands a meticulous, multi-stage manufacturing process, integrating cutting-edge technology with artisanal craftsmanship. The process at a leading couture dog clothes factory ensures precision, durability, and aesthetic excellence.

Step 1: Design & Pattern Prototyping

Utilizing advanced CAD (Computer-Aided Design) software, designers translate concepts into precise digital patterns. 3D modeling allows for virtual fitting and ergonomic assessment, ensuring optimal comfort and mobility for various breeds. Material selection is critical, focusing on hypoallergenic, breathable, and durable fabrics like organic cotton, merino wool, or performance-oriented synthetics with water-resistant or thermal properties.

Step 2: Material Sourcing & Inspection

Raw materials undergo rigorous quality control. Fabrics are inspected for defects, tensile strength, colorfastness (AATCC standards), and compliance with non-toxic certifications like OEKO-TEX Standard 100. This ensures materials are safe for pets and meet the aesthetic and functional requirements of the design.

Step 3: Precision Cutting (CNC Machining Equivalent)

Automated CNC fabric cutting machines, including laser cutters, are employed for unparalleled precision. These systems optimize material usage, reduce waste, and ensure every pattern piece is cut with exact dimensions, even for intricate designs or specialized fabrics. This is the textile equivalent of precise CNC machining in metalwork.

Step 4: Assembly & Stitching

Skilled technicians utilize specialized industrial sewing machines for various stitch types (e.g., flatlock for comfort, reinforced seams for durability). Advanced techniques like ultrasonic welding for waterproof seams are also deployed when required, ensuring structural integrity and longevity.

Step 5: Embellishment & Detailing

This stage involves applying intricate details such as embroidery, heat transfers, appliques, and attaching high-quality hardware (snaps, zippers, buckles). Many of these processes involve hand-finishing by experienced artisans, ensuring the "couture" aspect of the garments.

Step 6: Quality Assurance & Testing

Every garment undergoes rigorous multi-stage quality checks. This includes in-line inspections at each assembly stage and a comprehensive final inspection. Testing standards adhere to ISO 9001 quality management systems and relevant apparel testing protocols like ASTM D5034 for breaking strength and D3786 for bursting strength. Products are also tested for pet safety and comfort.

Step 7: Packaging & Logistics

Finished products are carefully packaged, often using eco-friendly materials, and prepared for distribution. Efficient logistics ensure timely delivery to global markets, maintaining product integrity during transit.

Technical Specifications & Material Innovation

The performance of pet apparel is intrinsically linked to the materials and manufacturing precision. A leading couture dog clothes factory prioritizes advanced textile engineering.

Table 1: Typical Material Specifications for High-Performance Pet Apparel

| Material Type | Key Properties | Application Focus | Testing Standards (Examples) |

|---|---|---|---|

| Organic Cotton | Soft, breathable, hypoallergenic, sustainable. | Everyday wear, sensitive skin. | GOTS certified, OEKO-TEX Standard 100. |

| Recycled Polyester (RPET) | Durable, moisture-wicking, quick-drying, eco-friendly. | Raincoats, activewear, fall clothes for dogs factory outerwear. | GRS (Global Recycled Standard), ASTM D5034. |

| Merino Wool Blends | Thermal regulation, odor resistance, soft, breathable. | Winter coats, base layers. | Woolmark certification, ISO 105-C06 (Colorfastness). |

| Technical Softshell Fabric | Water-resistant, windproof, breathable, flexible. | Outdoor jackets, protective gear. | ISO 811 (Hydrostatic Pressure), ISO 9237 (Air Permeability). |

Application Scenarios and Technical Advantages

The diverse product range from a dedicated couture dog clothes factory caters to myriad needs across various pet-related industries, from luxury boutiques to functional gear suppliers.

Typical Application Scenarios:

- Pet Retail & E-commerce: Supply of seasonal collections, trend-driven apparel, and bespoke items.

- Specialized Pet Services: Manufacturing uniforms for service animals, therapy dogs, or canine sporting events.

- Veterinary & Rehabilitation: Production of post-operative recovery suits or protective garments.

- Fashion & Lifestyle Brands: Collaborative ventures for pet apparel lines that complement human fashion collections.

Technical Advantages:

- Ergonomic Design: Patterns are engineered to accommodate canine anatomy, ensuring unrestricted movement and comfort, crucial for active breeds and service dogs.

- Durability & Longevity: Reinforced stitching, high-abrasion resistance fabrics, and robust hardware contribute to an extended service life, even under demanding conditions.

- Advanced Material Performance: Utilization of technical textiles that offer features like moisture-wicking, UV protection, thermal insulation, and anti-microbial properties. This is particularly vital for products like fall clothes for dogs factory produced garments where weather protection is paramount.

- Precision Manufacturing: The application of automated cutting and advanced sewing techniques minimizes defects and ensures consistent quality across large production runs.

- Customization Expertise: Capability to integrate client-specific branding, unique sizing charts, and specialized functional elements, offering unparalleled OEM/ODM solutions.

- Corrosion Resistance: For metallic components (zippers, buckles), selection of materials like stainless steel or coated alloys ensures longevity and safety against rust or degradation, particularly relevant in outdoor wear.

- Energy-Efficient Production: Modern facilities implement energy-saving technologies in cutting, sewing, and drying processes, reducing the environmental footprint of manufacturing.

Vendor Comparison: Choosing Your Manufacturing Partner

Selecting the right manufacturing partner is crucial for brand success. While many factories produce pet apparel, a specialized couture dog clothes factory offers distinct advantages.

Table 2: Manufacturer Comparison for Pet Apparel

| Feature | Specialized Couture Factory | Generic Apparel Manufacturer |

|---|---|---|

| Design & R&D | In-house design team, 3D prototyping, ergonomic focus, material innovation. | Basic pattern drafting, limited material expertise, often requires client-supplied designs. |

| Material Quality | Certified, performance-tested, pet-safe, sustainable options. | Standard fabrics, less focus on pet-specific safety or performance. |

| Manufacturing Precision | Automated CNC cutting, advanced stitching techniques, hand-finishing for details. | Manual cutting, basic machine stitching, mass production focus over intricate detail. |

| Quality Control | Multi-stage, ISO-certified QA, specific pet product testing (comfort, durability). | Standard QA, may not understand pet-specific wear and tear or safety. |

| Customization (OEM/ODM) | Full design collaboration, bespoke sizing, material development, private labeling. | Limited customization, primarily private labeling on existing designs. |

| Lead Time & MOQ | Optimized for complex projects, flexible MOQ for specialized products. | Variable, often high MOQs for cost efficiency, less flexible. |

Customized Solutions and OEM/ODM Capabilities

A true couture dog clothes factory differentiates itself through its ability to offer extensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This means catering to client-specific needs from concept to final product.

- Bespoke Design & Development: Collaborative design process, including mood boards, sketches, technical drawings, and prototype creation.

- Material & Trim Sourcing: Access to a global network of suppliers for specialized fabrics, eco-friendly options, and high-quality hardware.

- Private Labeling & Branding: Seamless integration of client logos, labels, and packaging designs, maintaining brand consistency.

- Scalable Production: Capacity to handle both limited-edition, high-end collections and larger production runs, adapting to market demand.

- Specialized Sizing: Development of custom size charts for specific dog breeds or product lines, ensuring optimal fit and comfort.

This flexibility is critical for brands looking to establish a unique presence in the competitive pet fashion market or seeking specialized fall clothes for dogs factory output.

Application Case Studies

Case Study 1: Luxury Pet Boutique "Paws & Elegance"

"Paws & Elegance," a high-end pet fashion brand, partnered with our couture dog clothes factory to launch its exclusive winter collection. The brand required bespoke designs featuring organic cashmere blends, intricate embroidery, and custom-designed metal clasps. Our factory's R&D team collaborated closely, providing 3D virtual prototypes for fit and style assessment. We sourced OEKO-TEX certified cashmere and utilized laser-guided cutting for precision patterns. The final collection passed rigorous comfort and durability testing, leading to a 30% increase in customer satisfaction and a significant boost in seasonal sales for "Paws & Elegance."

This partnership underscored the factory's capability in delivering exceptional quality for luxury segments, maintaining tight control over material integrity and design fidelity.

Case Study 2: Eco-Friendly Pet Supply Brand "Green Paws" and Cat Litter Production

"Green Paws," an emerging brand focused on sustainable pet products, sought a manufacturing partner for their new line of fresh & natural cat litter manufacturer. They needed a supplier capable of producing a dust-free, strong clumping bentonite cat litter with a commitment to environmentally responsible sourcing and packaging. Our factory, recognized not only as a couture dog clothes factory but also for its broader pet product manufacturing expertise, provided a comprehensive solution.

We leveraged our established supply chain for high-grade bentonite and implemented a specialized dust-removal process. The product, 'China Factory 5L Dust Free Strong Clumping Bentonite Cat Litter', met all "Green Paws" specifications for clumping strength (95% at 5 minutes) and dust levels (below 0.5%). This successful collaboration highlighted our factory's versatility as a fresh & natural cat litter supplier, demonstrating the same commitment to quality and technical precision across different pet product categories.

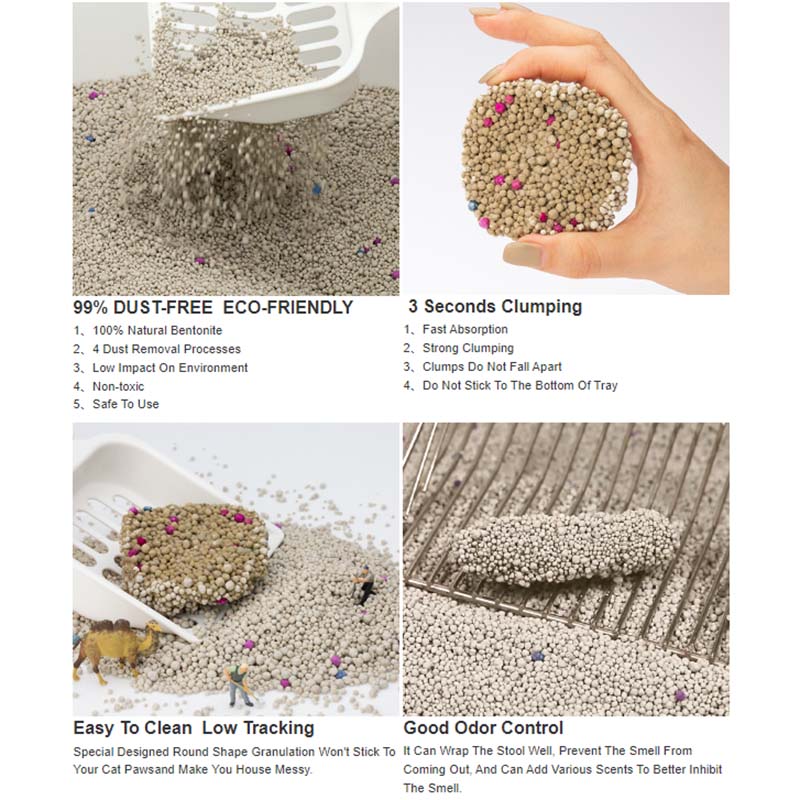

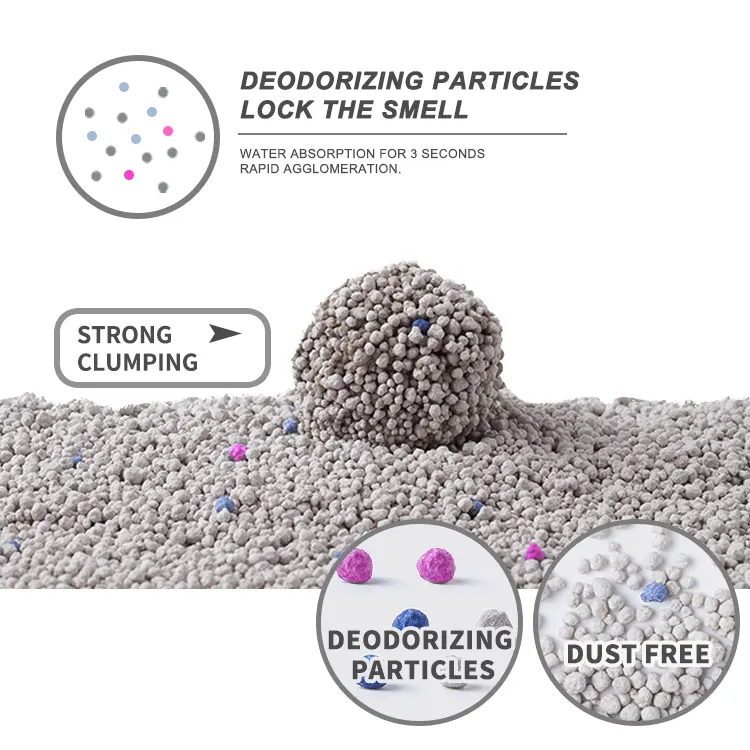

Product Spotlight: China Factory 5L Dust Free Strong Clumping Bentonite Cat Litter

As a testament to our diversified manufacturing capabilities, beyond our expertise as a couture dog clothes factory, we proudly present an example of our high-quality pet consumable products. Our "China Factory 5L Dust Free Strong Clumping Bentonite Cat Litter" exemplifies the rigorous quality control and technical specifications applied across our entire product portfolio.

Table 3: Product Specifications – China Factory 5L Dust Free Strong Clumping Bentonite Cat Litter

| Parameter | Specification | Benefit |

|---|---|---|

| Main Material | 100% Natural Sodium Bentonite | Safe, non-toxic, highly absorbent. |

| Packaging Size | 5 Liters (Approx. 4.2 kg) | Convenient for single-cat households, easy handling. |

| Dust Level | Less than 0.5% | Minimizes respiratory issues for pets and owners, cleaner home environment. |

| Clumping Strength | ≥95% at 5 minutes | Superior waste encapsulation, easy scooping, less odor. |

| Odor Control | High natural absorption, optional activated carbon infusion. | Neutralizes strong odors, ensuring a fresh environment. |

| Granule Size | 0.5mm - 2.5mm | Optimal for paw comfort, reduces tracking. |

| Water Absorption | >300% | Maximizes liquid retention, prolongs litter lifespan. |

Quality Assurance and Certifications (Authoritativeness)

Maintaining industry-leading standards is paramount. As a top-tier manufacturer for both specialized apparel and pet consumables, our factory adheres to stringent international quality and safety certifications.

- ISO 9001:2015 Certification: Our Quality Management System ensures consistent product quality and continuous improvement across all manufacturing processes, from a couture dog clothes factory to fresh & natural cat litter manufacturer operations.

- OEKO-TEX Standard 100: Applied to all textile products, this certification guarantees that fabrics and materials used in pet apparel are free from harmful substances and are safe for pet contact.

- Global Organic Textile Standard (GOTS): For organic cotton and other natural fiber-based apparel, ensuring ecological and social criteria are met throughout the entire supply chain.

- FDA Compliance (for Pet Consumables): Our cat litter production adheres to relevant FDA guidelines for pet products, ensuring safety and quality of raw materials.

- Years of Service & Client Portfolio: With over 15 years of experience in pet product manufacturing, we have cultivated partnerships with leading global pet brands, demonstrating sustained reliability and expertise.

Our internal testing protocols, including material analysis, performance testing, and safety assessments, ensure every product surpasses industry benchmarks.

Client Trust and Support (Trustworthiness)

Frequently Asked Questions (FAQ)

Q: What is your minimum order quantity (MOQ) for custom dog clothes?

A: Our MOQ for custom couture dog clothes typically starts from 200-500 units per design, depending on complexity and material sourcing. We offer flexibility for initial prototype runs or specialized limited editions.

Q: Can you help with design and material selection for new pet apparel lines?

A: Absolutely. Our in-house design and R&D teams provide comprehensive support, from concept development and 3D modeling to expert advice on material properties, sustainability, and trend forecasting for fall clothes for dogs factory output and beyond.

Q: What are your lead times for production?

A: Typical lead times range from 30-60 days after sample approval and deposit, depending on the order volume, product complexity, and material availability. Expedited options may be available for urgent requests.

Q: Do you offer private labeling for both apparel and cat litter products?

A: Yes, we provide extensive private labeling and white label solutions for both pet apparel and pet consumables like our fresh & natural cat litter manufacturer services. This includes custom branding, packaging design, and fulfillment tailored to your brand identity.

Lead Time & Fulfillment Details

Our streamlined supply chain and robust production planning ensure efficient order fulfillment. We manage global logistics, offering various shipping options (FOB, CIF, DDP) to meet client requirements. Regular updates are provided throughout the production and shipping phases.

Warranty Commitments

We stand by the quality of our products. All apparel and consumables come with a standard manufacturing warranty against defects in materials and workmanship. Specific warranty terms are outlined in our B2B contracts, ensuring client confidence and satisfaction.

Customer Support Information

A dedicated account manager is assigned to each client, serving as a single point of contact for all inquiries, from design iterations to logistical support. Our technical support team is available to address any product-specific questions or challenges, ensuring a seamless partnership experience.

Conclusion

The modern pet industry demands manufacturing partners who combine technical prowess with an understanding of evolving market needs. A leading couture dog clothes factory embodies this, offering not only precision-engineered apparel but also diversifying into essential pet consumables as a reliable fresh & natural cat litter supplier. This dual capability, underpinned by rigorous quality assurance, cutting-edge technology, and a client-centric approach, positions our factory as an indispensable partner for brands aiming for excellence in the global pet market. By choosing a manufacturer with such comprehensive expertise, businesses can ensure their products stand out in terms of quality, innovation, and ethical production.

References

- Grand View Research. (2023). Pet Apparel Market Size, Share & Trends Analysis Report.

- Textile Exchange. (2022). Global Recycled Standard (GRS) – Factsheet.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality Management Systems – Requirements.

- OEKO-TEX Association. (2023). Standard 100 by OEKO-TEX® – Fact Sheet.

- American Society for Testing and Materials (ASTM). (2022). ASTM D5034-09(2022) Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test).