- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Couture Dog Clothes Factory: Luxury & Bespoke Pet Apparel Mfg.

Industry Trends in Couture Canine Apparel Manufacturing

The luxury pet market is experiencing unprecedented growth, driven by an increasing humanization of pets and a desire for high-quality, bespoke items. This trend extends significantly to pet fashion, where discerning owners seek unique, durable, and comfortable apparel for their canine companions. The demand for specialized manufacturers, particularly a couture dog clothes factory, has surged. Clients are not just looking for off-the-rack solutions but are increasingly requesting custom designs, specialized materials, and ethical production practices. This shift emphasizes the need for factories that combine traditional craftsmanship with modern manufacturing capabilities, offering both OEM and ODM services.

Key trends include a focus on sustainable and eco-friendly materials, ergonomic designs that ensure pet comfort and mobility, and the integration of smart textiles for features like temperature regulation or GPS tracking. There's also a rising interest in themed collections, such as fall clothes for dogs manufacturer lines, which require agile design and production capabilities to meet seasonal demands. High-end pet boutiques and luxury lifestyle brands are continuously seeking reliable partners to bring their exclusive apparel visions to life.

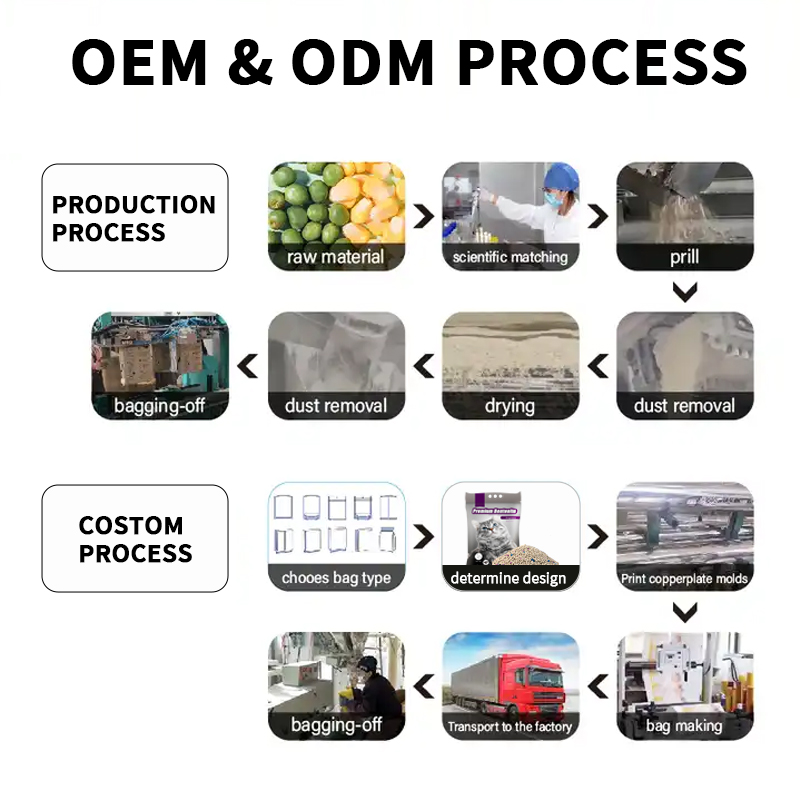

The Meticulous Process of a Couture Dog Clothes Factory

The manufacturing process within a couture dog clothes factory is a sophisticated orchestration of design, material science, and precision craftsmanship. It ensures that each garment meets stringent quality and aesthetic standards for the high-end pet market. The typical process flow, whether for bespoke creations or specialized production runs, follows a series of carefully managed stages:

1. Design & Concept Development

- Client Consultation & Briefing: Detailed discussion of client vision, target market, specific design elements, and functional requirements. This includes aesthetic preferences, color palettes, and seasonal considerations, such as for fall clothes for dogs manufacturer lines.

- Sketching & Digital Design: Translating concepts into detailed sketches and digital renderings, often utilizing CAD software for precision.

- Material Sourcing & Selection: Identifying and sourcing premium fabrics (e.g., merino wool, cashmere, silk, organic cotton, technical waterproof membranes) and embellishments (e.g., Swarovski crystals, custom embroidery, bespoke hardware). Emphasis is placed on durability, comfort, non-toxic properties, and aesthetic appeal.

2. Pattern Making & Prototyping

- Pattern Grading: Developing precise patterns tailored to various dog breeds and sizes, ensuring ergonomic fit and freedom of movement. This involves intricate knowledge of canine anatomy.

- Sample Production: Creation of initial prototypes for fit testing, material drape assessment, and design validation.

- Client Feedback & Revisions: Iterative process of adjustments based on client and in-house expert feedback until the prototype perfectly matches specifications.

3. Fabrication & Assembly

- Precision Cutting: Utilizing advanced cutting technologies (e.g., CNC fabric cutters) to ensure accuracy, especially for complex patterns or delicate materials.

- Sewing & Construction: Skilled artisans employ specialized sewing techniques (e.g., flatlock stitching for comfort, reinforced seams for durability, bespoke tailoring methods) to assemble garments. This stage includes attachment of linings, interfacings, and structural components.

- Embellishment & Finishing: Hand-applied details such as embroidery, beadwork, crystal application, custom hardware fitting, and label attachment.

4. Quality Control & Testing

- Material Testing: Fabrics undergo tests for colorfastness (ISO 105), tensile strength (ISO 13934), pilling resistance (ISO 12945), and pet-safe chemical compliance.

- In-Process Inspections: Each stage of manufacturing includes rigorous checks for stitching quality, seam integrity, and adherence to design specifications.

- Final Product Audit: Comprehensive inspection of the finished garment for aesthetic perfection, functional integrity, and compliance with all client requirements and safety standards (e.g., European Pet Safety Standards, ASTM F963 for child-friendly materials if applicable for pet toys/accessories).

- Durability Testing: Simulated wear and tear tests to ensure longevity, especially for active dog apparel.

5. Packaging & Logistics

- Premium Packaging: Garments are carefully packaged in custom, protective packaging suitable for luxury items.

- Shipping & Distribution: Coordinated logistics to ensure timely and secure delivery to clients worldwide.

Technical Specifications and Advantages

A leading couture dog clothes factory distinguishes itself through its adherence to superior technical specifications and the resulting functional and aesthetic advantages. These elements are critical for B2B partners seeking reliability and excellence.

Key Technical Parameters and Product Specifications

| Parameter | Specification/Detail | Standard/Notes |

|---|---|---|

| Fabric Composition | 100% Organic Cotton (GOTS certified), Merino Wool (RWS certified), Waterproof Polyester (PFC-free DWR), Silk blends | OEKO-TEX Standard 100, Hypoallergenic options |

| Fabric Weight (GSM) | Light (150-250 GSM), Mid (250-400 GSM), Heavy (400+ GSM) | Optimized for climate and garment type (e.g., winter coats for higher GSM) |

| Stitching Type | Flatlock, Overlock (5-thread safety), Double-needle, Bar-tack reinforcement | Ensures durability, comfort, and prevents fraying |

| Hardware & Fastenings | Nickel-free metal snaps, YKK zippers, custom engraved buckles, Velcro (pet-friendly) | Corrosion resistance, pull-strength tested (e.g., ANSI B30.20), non-toxic coatings |

| Colorfastness | Grade 4-5 (on a 1-5 scale) | ISO 105-C06 (Washing), ISO 105-B02 (Light), ensuring longevity of vibrant colors |

| Water Resistance (for outerwear) | Hydrostatic Head: 10,000mm - 20,000mm | ISO 811, suitable for heavy rain and snow; seam-sealed for full waterproofing |

Technical Advantages for B2B Clients

- Precision Fit & Ergonomics: Advanced pattern-making techniques ensure garments conform to canine anatomy without restricting movement, crucial for comfort and wearability. This reduces return rates for luxury brands.

- Material Expertise: Access to a global network of premium, certified material suppliers allows for selection of fabrics with specific properties – be it hypoallergenic, ultra-soft, breathable, or high-performance waterproof textiles. This is vital for specialized collections, such as fall clothes for dogs supplier lines that require specific insulation and weather protection.

- Durability & Longevity: Robust construction, reinforced stress points, and quality hardware ensure a service life far exceeding standard pet apparel, upholding the integrity of luxury brands.

- Aesthetic Excellence: Masterful embellishment, precision stitching, and meticulous finishing contribute to a product that is visually stunning and tactilely superior, elevating brand perception.

- Scalable Customization: While offering bespoke solutions, the factory also possesses the infrastructure to scale production for larger orders while maintaining individual garment quality and customization options.

- Ethical & Sustainable Production: Adherence to ethical labor practices and sourcing of sustainable materials provides a significant advantage for brands committed to corporate social responsibility, appealing to a growing segment of conscious consumers.

Application Scenarios & Vendor Comparison

The services of a specialized couture dog clothes factory are invaluable across various high-end market segments, providing tailored solutions for specific needs.

Typical Application Scenarios

- Luxury Pet Boutiques: Developing exclusive, limited-edition collections that differentiate their offerings and cater to an affluent clientele seeking unique designs.

- High-End Fashion Brands (Pet Lines): Extending established fashion houses into the pet sector, maintaining brand aesthetic and quality standards for canine apparel and accessories.

- Pet Event & Show Organizers: Creating custom uniforms or themed outfits for pet fashion shows, competitive events, or promotional activities, demanding precision and visual impact.

- Celebrity Stylists & Bespoke Clients: Providing one-off, highly customized garments for celebrity pets or clients with specific, often elaborate, design requests.

- Specialized Performance Wear: Manufacturing durable, functional apparel for working dogs or dogs participating in specific sports, requiring technical fabrics and ergonomic design. For instance, cold-weather gear from fall clothes for dogs factories is critical for canine performance in challenging climates.

Vendor Comparison: Couture vs. Mass Production

Choosing the right manufacturing partner is paramount. Below is a comparison highlighting the distinct advantages of a couture dog clothes factory over a general mass-production facility.

| Feature | Couture Dog Clothes Factory | Mass Production Factory |

|---|---|---|

| Design Philosophy | Bespoke, unique, high-fashion, trend-setting. | Standardized, volume-driven, basic functional designs. |

| Material Sourcing | Premium, ethically sourced, specialized, performance-oriented fabrics and embellishments. | Cost-effective, readily available, standard textiles. |

| Craftsmanship | Hand-finished details, intricate tailoring, advanced sewing techniques, artisan input. | Automated processes, basic stitching, minimal finishing. |

| Fit & Sizing | Ergonomic, breed-specific patterns, custom adjustments for perfect fit. | Standardized sizing (S, M, L), often generic fit. |

| Quality Control | Rigorous multi-stage inspections, material testing, performance audits, certified standards (e.g., ISO 9001, pet safety standards). | Batch testing, statistical sampling, focus on defect rates. |

| Minimum Order Quantity (MOQ) | Flexible, often lower MOQs for bespoke designs, higher for repeatable collections. | High MOQs, typically thousands of units per SKU. |

Customized Solutions & Application Case Studies

The essence of a leading couture dog clothes factory lies in its ability to offer comprehensive customized solutions, transforming unique visions into tangible, high-quality products. This is especially critical for brands seeking to establish a distinctive market presence.

Customization Capabilities

- OEM (Original Equipment Manufacturing): Full production based on client-provided designs, specifications, and materials. The factory meticulously executes the client's existing blueprint, ensuring exact replication and quality adherence.

- ODM (Original Design Manufacturing): Collaborative design and manufacturing. The factory leverages its in-house design expertise to develop collections from concept, often based on client briefs, market trends, or seasonal themes (e.g., fall clothes for dogs factories developing new autumn lines). This includes material suggestions, pattern development, and sampling.

- Bespoke Tailoring: Creating unique, one-off garments for individual clients or specific events, requiring precise measurements and personalized design elements.

- Private Labeling: Applying client branding, labels, and packaging to manufactured garments, ensuring brand consistency.

- Material Innovation: Expertise in working with novel materials, including smart textiles (e.g., temperature-regulating fabrics), sustainable alternatives (e.g., recycled polyester, plant-based leathers), and performance fabrics (e.g., highly breathable, waterproof, anti-microbial).

Real-World Application Case Studies (Simulated)

Case Study 1: Luxury Canine Apparel Line for an International Fashion House

Client Need: A renowned European luxury fashion house sought to launch a premium pet accessories line, requiring impeccably crafted dog coats and sweaters that mirrored their human apparel's aesthetic and quality. They needed an ODM partner capable of interpreting their brand identity into canine wear.

Solution by Factory: Our couture dog clothes factory team collaborated extensively with the fashion house's designers. We proposed an exclusive line featuring cashmere-blend sweaters with intricate intarsia knit patterns and tailored wool coats with custom-designed hardware. Our pattern experts ensured the garments offered a sophisticated silhouette while allowing full freedom of movement for various breeds. Fabric was sourced adhering to OEKO-TEX standards, and ethical production was paramount. The collection achieved critical acclaim, establishing the brand's presence in the luxury pet market.

Outcome: Successful launch of a high-margin pet apparel line, increased brand loyalty, and expansion into a new lucrative market segment. The client noted exceptional craftsmanship and customer feedback highlighting the garments' superior fit and luxurious feel.

Case Study 2: Specialized Cold-Weather Gear for Arctic Exploration Dogs

Client Need: An Antarctic research expedition required highly durable, insulated, and waterproof protective gear for their working sled dogs. The apparel needed to withstand extreme sub-zero temperatures, abrasion, and moisture, while ensuring canine comfort and mobility during strenuous activity. They specifically sought a fall clothes for dogs supplier with technical textile expertise.

Solution by Factory: Leveraging our expertise in technical fabrics and robust construction, we designed and manufactured a specialized suit. This involved a multi-layer system: an outer shell of 20,000mm waterproof, ripstop Cordura fabric with fully sealed seams, a mid-layer of advanced synthetic insulation (PrimaLoft equivalent), and an inner lining of moisture-wicking fleece. All hardware was designed for extreme cold use. Prototypes underwent rigorous testing in simulated cold chambers to ISO 22778 standards for thermal insulation. The final product provided unparalleled protection without hindering the dogs' performance.

Outcome: Enhanced safety and performance for expedition dogs, significantly reducing risks of hypothermia and frostbite. The client praised the gear's exceptional durability and the factory's innovative approach to extreme-condition apparel.

Trustworthiness & Client Support

Building and maintaining trust is fundamental in B2B partnerships. Our commitment to transparency, clear communication, and robust support systems ensures client confidence from initial concept to post-delivery.

Frequently Asked Questions (FAQ)

Q1: What is your typical Minimum Order Quantity (MOQ) for custom couture dog clothes?

A1: Our MOQs are flexible and depend on the complexity of the design and materials selected. For bespoke or highly customized luxury items, MOQs can start as low as 50-100 units per design. For more standardized collections, such as a seasonal fall clothes for dogs manufacturer line, it may be 300-500 units. We encourage clients to discuss their specific project needs for a tailored quote.

Q2: What certifications does your factory hold?

A2: We operate under ISO 9001:2015 certified quality management systems. Our materials are sourced from OEKO-TEX Standard 100 certified suppliers, ensuring they are free from harmful substances. We also adhere to international labor standards and ethical sourcing practices.

Q3: Can you assist with design and pattern development?

A3: Absolutely. As an ODM factory, we offer full design and pattern development services. Our in-house design team can work from your initial concepts, sketches, or mood boards to create detailed technical specifications, patterns, and prototypes that meet your vision and market demands.

Lead Time & Fulfillment

- Sample Production: Typically 2-4 weeks, depending on design complexity and material availability.

- Mass Production: General lead times range from 8-12 weeks after sample approval and deposit, varying by order volume, material lead times, and current production schedule. We prioritize transparent communication regarding timelines.

- Expedited Services: Expedited options may be available for urgent projects, subject to additional fees and scheduling confirmation.

Warranty & After-Sales Support

- Quality Guarantee: All products from our couture dog clothes factory come with a comprehensive quality guarantee against manufacturing defects. Any issues identified upon receipt that deviate from approved samples or specifications will be addressed promptly.

- Defect Resolution: In the rare event of manufacturing defects, we commit to repair, replace, or offer credit for affected units as per agreed terms, ensuring minimal disruption to your business.

- Dedicated Account Management: Each client is assigned a dedicated account manager who serves as a single point of contact for all inquiries, from order placement to post-delivery support, ensuring seamless communication and problem resolution.

- Feedback Integration: We actively solicit client feedback to continuously improve our processes and product quality, fostering long-term, mutually beneficial partnerships.

References

- International Organization for Standardization (ISO). ISO 9001:2015 - Quality management systems - Requirements.

- OEKO-TEX Association. OEKO-TEX Standard 100.

- Global Organic Textile Standard (GOTS). Version 6.0, 2020.

- Responsible Wool Standard (RWS). Textile Exchange, 2021.

- ASTM International. ASTM F963-17 - Standard Consumer Safety Specification for Toy Safety. (Referenced for pet-friendly material safety).